Introduction

Mechanical engineering is a diverse and dynamic field that relies on a wide range of materials to design and construct innovative solutions for real-world challenges. These materials serve as the building blocks for everything from aerospace components to consumer products. In this blog, we will explore the essential materials used in mechanical engineering, their properties, applications, and the pivotal role they play in shaping the modern world.

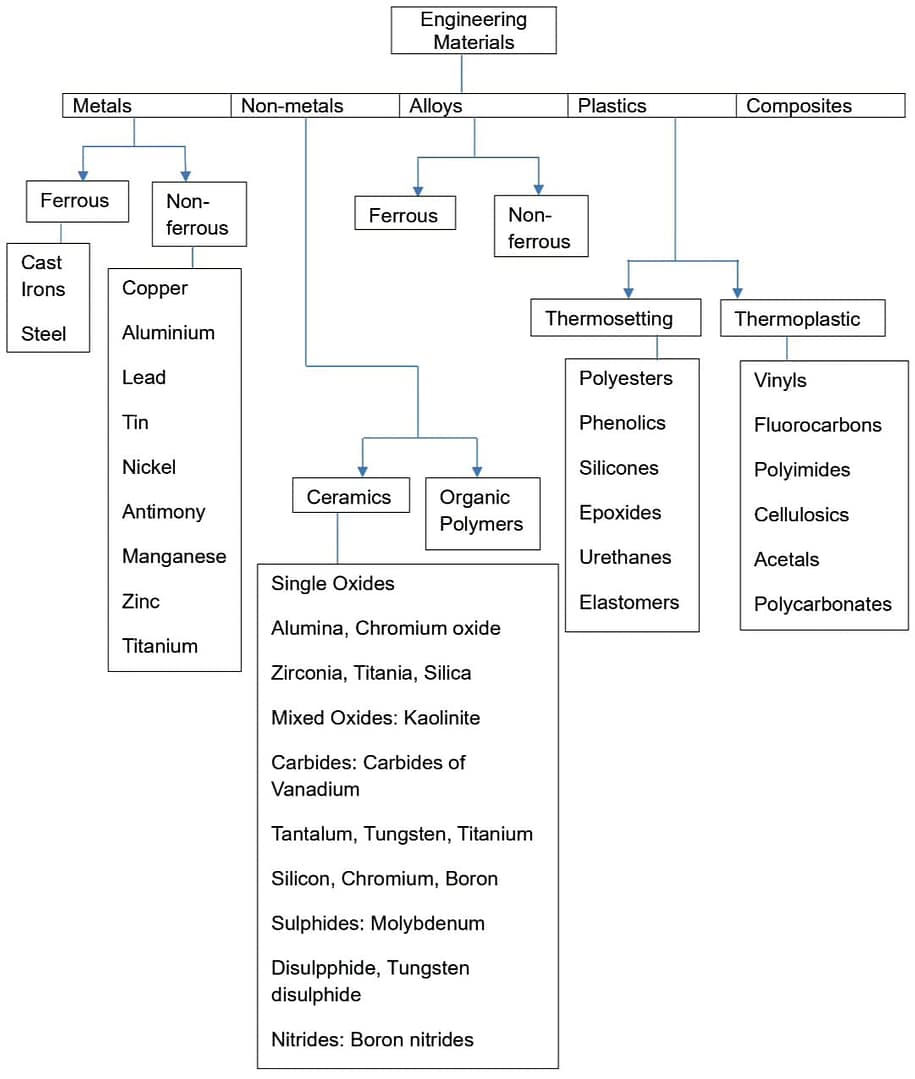

Engineering materials play a key role in manufacturing machines and structures. Engineers classify these materials as metals, non-metals, plastics, or composites. To apply them effectively, one must understand their behavior under various conditions. This section focuses specifically on cast irons, steels, and their alloys.

Classification of engineering materials

The engineering materials may be broadly classified into two groups:

- Metallic materials

- Non-metallic materials

The metallic materials may be further split into (a) ferrous materials, and (b) non-ferrous materials.

Non-metallic materials include plastics, rubber, leather, carbon, wood, glass, etc.Below there is a few categories of materials which is used in mechanical engineering.

Ferrous materials consist mainly of iron with small addition of other materials. Steels contain carbon upto 2 %. Non-ferrous materials contain very little or no iron. These materials include Aluminium. Magnesium, Copper, Zinc, Tin, Lead, Nickel, Titanium and so on and their alloys.

1. Metals

- Steel: Known for its strength and flexibility, steel is widely used in the construction field as well as automobile industry also aviation sector. Steel can also be made into suitable material for different applications by alloying it with various elements.

- Aluminum: Aluminum is durable, weighs little and has good heat conductive properties as well electricity. It is very popular in aerospace, automotive and packaging industries.

- Copper: Copper is the perfect material for electrical wiring and components due to its high level of both electrically conductivity, as well as thermally. It is also found in heat exchangers and plumbing.

- Titanium: Titanium is renowned for its unparalleled strength-to-weight ratio and can be found in aerospace, medical implants, as well as sporting goods. Its corrosion protection is also a strength in marine use.

2. Polymers

Polymers are lightweight, cost-effective, and offer excellent design flexibility, making them indispensable in mechanical engineering:

- Plastics: Plastics find applications in a plethora of areas ranging from simple consumer goods to automotive components. There are different types of them, which differ in their characteristics.

- Composites: Composite materials have a high strength-to-weight ratio, including carbon fiber reinforced polymers (CFRP). Engineers and manufacturers widely use them in the aerospace, automotive, and sporting goods industries.

- Elastomers: Elasticity and damping properties of rubber-like materials, natural or synthetic as well. Applications include tires, seals and shock absorbers.

3. Ceramics

Ceramics offer high hardness, resist heat effectively, and insulate against electricity.They find applications in mechanical engineering for various purposes:

- Alumina: Alumina ceramics are often used as insulators, cutting tools, and wear-resistant components in harsh environments.

- Zirconia: Zirconia ceramics have high strength and excellent wear resistance. They are used in medical implants, bearings, and cutting tools.

4. Composites

- Fiber-Reinforced Composites: These materials use fibers (such as carbon or glass) embedded in a matrix (often a polymer) to provide high strength and lightweight properties. They are used in aerospace, automotive, and sporting goods.

- Metal Matrix Composites: These composites combine metal matrices with reinforcing materials like silicon carbide, offering improved strength, heat resistance, and wear resistance for applications like brakes and heat sinks.

Properties of engineering materials

Chemical Properties

- Composition-is the elemental or chemical components that make up materials and their relative proportions.

- Microstructure- is the structure of a polished and etched metal as revealed by microscope magnifications greater than ten diameters.

- Crystal Structure-is the ordered, repeating arrangement of atoms or molecules in a material.

- Corrosion Resistance-is the ability of a material to resist deterioration by chemical or electrochemical reaction with its environment.

Physical Properties

- Melting Point- at which a material liquefies on heating or solidifies on cooling.

- Density-is the mass of a material per unit volume.

- Specific Gravity-is the ratio of the mass or weight of a solid or a liquid to the mass or weight of an equal volume of water.

- The Curie point marks the temperature at which ferromagnetic materials lose their ability to become magnetized by external forces.

- Refractive index-is the ratio of the velocity of light in vacuum to its velocity in another material.

- Thermal Conductivity-is the rate of heat flow in a homogeneous material under steady-state conditions, per unit area, per unit temperature gradient in a direction perpendicular to area.

- Thermal expansion describes how quickly a material elongates when it heats up. Engineers express this rate as the increase in length per unit rise in temperature within a defined temperature range.

- Heat Distortion Temperature-is the temperature at which a polymer under a specified load shows a specified amount of deflection.

- Water absorption measures how much weight a polymer gains, expressed as a percentage, after it absorbs water during a controlled immersion for a specific period.

- Dielectric Strength-is the highest potential difference that an insulating material of given thickness can withstand for a specified time without occurrence of electrical breakdown through its bulk.

- Electrical Resistivity-is the electrical resistance of a material per unit length and crosssection area or per unit length and unit weight.

- Specific heat compares the heat needed to raise the temperature of a unit mass of a substance by 1°C to the heat required to raise the same mass of water by 1°C.

- Poisson’s Ratio-is the absolute value of the ratio of the lateral or transverse strain to the longitudinal strain.

- Colour-is the property of light by which an observer may distinguish between two structure free patches of light of the same size and shape.

Mechanical Properties

- Tensile (Ultimate) Strength-is the ratio of maximum load to original area of cross-section.

- Yield Strength-is the stress at which a material exhibits a specified deviation from proportionality of stress and strain.

- Compressive Strength-is the maximum compressive stress based upon original area that a material is capable of withstanding.

- Modulus of Elasticity-is the ratio of stress to strain in a material within the elastic limit.

- Flexural strength indicates the outer fiber stress a material develops when it undergoes bending as a simply supported beam under a specific strain.

- Shear strength measures the stress that causes a material to fracture along its cross-sectional plane.

- Percentage elongation expresses how much the gauge length increases after the specimen fractures, calculated as a percentage of its original length.

- Percentage Reduction in Area-the difference, expressed as a percentage of original area, between the original area of cross-section of a tensile test specimen and the minimum area of cross-section measured after fracture.

- Hardness-is the resistance of a material to plastic deformation, abrasion, scratching or indentation.

- Impact strength measures the energy a material requires to fracture a given volume.

- Endurance Limit-is the maximum stress below which a material can theoretically endure an infinite number of stress cycles.

- Creep-is the continuous flow of a material under constant temperature and stress.

- Creep Strength-is the constant nominal stress that will cause a specified quantity of creep in a given time at constant temperature.

- Stress Rupture Strength-is the nominal stress at fracture in a tension test at constant load and constant temperature.

- Mechanical properties play a crucial role in selecting materials for structural machine components. Figure 1 lists the properties required for serviceability.

Dimensional properties

- Roughness refers to the finely spaced surface irregularities that form a distinct pattern through their height, width, and direction.

- Waviness-is a wavelike variation from a perfect surface; generally much wider in spacing and higher in amplitude than surface roughness.

- Lay-is the direction of a predominating surface pattern, usually after a machine operation.

- Camber-is the maximum deviation from edge straightness.

- Microtopography-is the microscopic characteristics that describe a surface.

Technological Properties

- Machinability-is describes how easily a material allows machining.

- Weldability-is describes how easily a material allows welding.

- Castability-is describes how easily a material forms into castings.

- Malleability-is allows a material to roll easily into sheets.

- Forgibility-is allows a material to undergo forging with ease.

- Bendability-is enables a material to bend easily.

- Ductility-is allows a material to draw easily into wires.

- Hardenability-is describes how easily a material hardens when subjected to heat treatment.