Introduction

Every vehicle relies on engines to power their movement and ensure proper functioning. Understanding the different components of an engine is important for enthusiasts and mechanics, whether they are working on cars, motorcycles or boats. Let's delve into the intricate world of engine parts to grasp how they work together to produce power.

Components of an Engine

1.Cylinder Block

The cylinder block forms the core structure of the engine and houses the cylinders where combustion occurs. Manufacturers typically use cast iron or aluminum to construct it. The block includes various passages that circulate coolant and oil throughout the engine.

2.Crank Case

- It forms the lower part of the engine. It accommodates crankshaft. The crankshaft is a long straight piece of metal in a vehicle that connects the engine to the wheels and helps turn the engine’s power into movement.

- The crankshaft rests on supports at both ends inside the crankcase walls. The crankcase provides these support points. In engines with longer crankshafts, engineers also place an additional support in the middle, and the crankcase includes a provision for that central support as well.

3.Cylinder Head

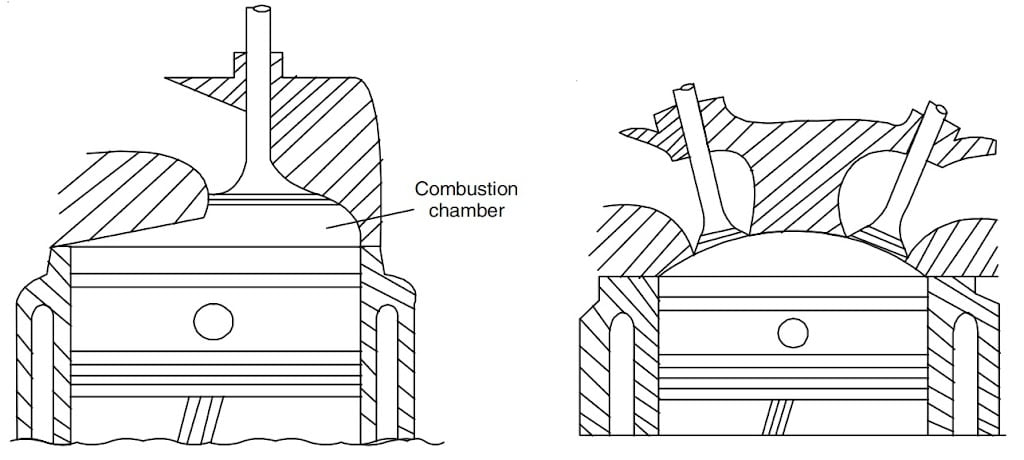

- Cylinders are where the magic happens.They provide the space for the piston to move up and down during the combustion cycle.Engines can have different numbers of cylinders, such as four-cylinder, six-cylinder, or eight-cylinder configurations.

- Engineers design the cylinder head to hold the inlet and exhaust valves. It also forms the top part of the combustion chamber. Designers shape the combustion chamber in various ways to achieve effective fuel combustion.

- Manufacturers use cast iron or aluminum alloy to make the cylinder head. They machine the surface to ensure smooth installation of various components.

- Engineers install a cover on the cylinder heads to prevent noise and vibration from reaching the automobile body. They make the cover using a three-layer sheet: the outer two layers consist of metal, while the middle layer contains plastic. This plastic layer blocks the transmission of noise and vibration from the engine.

4.Piston

- Pistons play a crucial role by moving within the cylinders. They connect to the crankshaft through connecting rods and perform a reciprocating motion. The combustion force pushes the piston downward and converts thermal energy into mechanical energy.

- The piston moves inside the cylinder and has reciprocatory motion. It is air tight and does not allow the leakage of charge and hot gases with the help of rings which form a part of piston ring assembly.

- In addition, it transmits the impact produced by gases at high temperature and pressure. Furthermore, it accommodates the small end of the connecting rod. Moreover, it takes the lateral thrust resulting from the obliquity of the connecting rod. As a result, it plays a crucial role in maintaining the mechanical balance and structural integrity of the engine during operation.

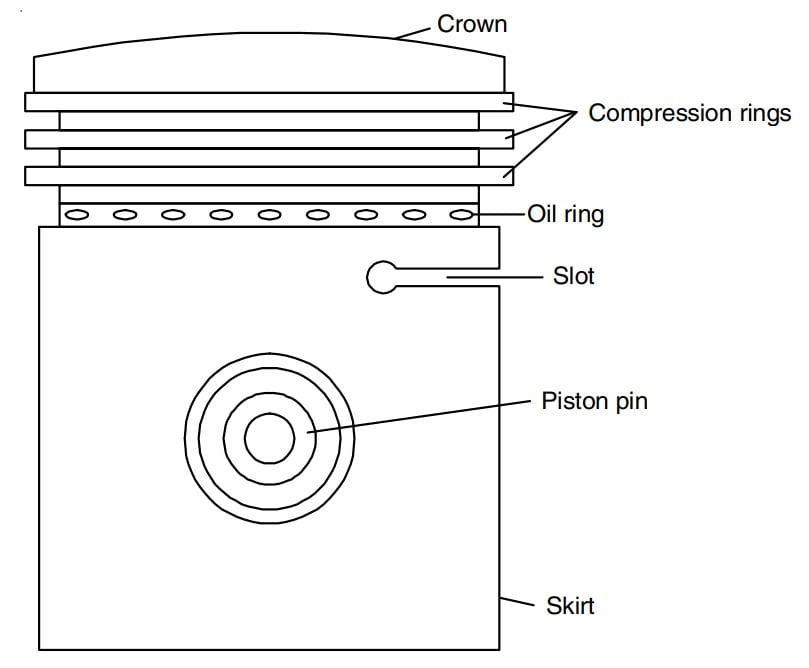

- The top portion of the piston, called the crown, forms the upper surface of the piston. The piston assembly includes piston rings and a piston pin as integral parts. The skirt forms the lower-most part of the piston. Engineers provide a slot in the piston to accommodate specific mechanical requirements.

- The slot accommodates the expansion of piston material when hot.This helps in reducing the clearance between skirt and cylinder bore when cold. When hot,the slot accommodates the expansion of piston material.

- Typically, engineers most commonly use aluminum alloy to make pistons. Specifically, this alloy contains about 12% silicon, which helps reduce the coefficient of expansion when compared to pure aluminum and cast iron. In addition, manufacturers add phosphorus to the alloy. As a result, the fatigue resistance of the pistons is significantly enhanced. Consequently, these material improvements contribute to better engine durability and performance.

- Addition of cobalt and chromium further reduces the co-efficient of expansion which makes piston suitable for use when proper cooling many not be possible.Piston rings and piston pin are the components of piston sub-assembly. The outer surface of the piston ring is in close contact with the inner surface of the cylinder. The ring becomes perfect circle in the cylinder. In unassembled state, when left free, it is slightly oval.

- Engineers refer to the rings as compression rings when they prevent hot flue gases from leaking during the expansion stroke. In large engines, designers also include oil rings to lubricate the piston sub-assembly.

5.Connecting Rod

6.Crankshaft

-

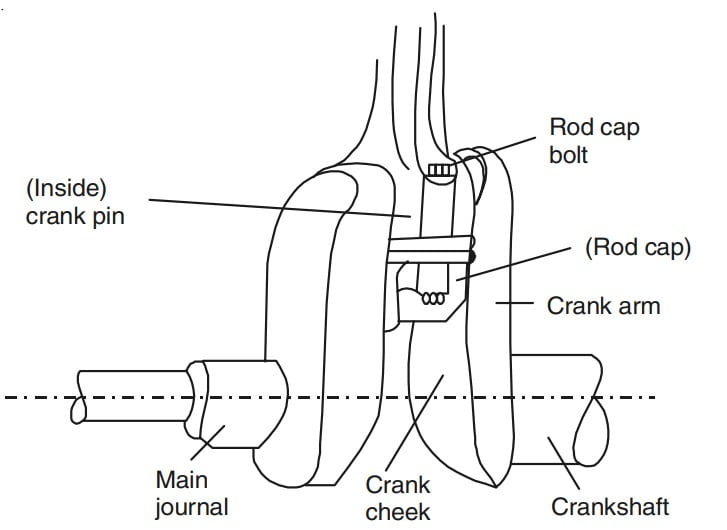

Engineers must study the crankshaft in detail because it serves as a crucial component in an automobile engine. Automobiles typically use multicylinder engines. The unique shape and loading conditions of a multicylinder engine's crankshaft demand special attention from designers.

-

A crankshaft fundamentally converts the reciprocating motion of the pistons into rotational motion. It applies the principle of the simple machine known as the wheel and axle. Manufacturers typically forge or cast the crankshaft from steel. They then machine it to create suitable journals for both the connecting rod and the main bearings. This precise construction ensures efficient power transmission and smooth engine operation.

- To begin with, engineers call the parts of the crankshaft that extend from the main bearing journal to the connecting rod bearing journals crank arms or cheeks. The crank arm length directly determines the engine's stroke. In fact, the distance from the center of the main bearing journal to the center of the connecting rod bearing journal equals half the engine stroke. This measurement directly defines engine displacement and influences performance characteristics.

- The part of the crank shaft inside the connecting rod bearings is called the crank pin and those inside the main bearings are called the main journals (Fig. 6).

- The number of main bearings varies with the design of the engine and number of cylinders. There must be atleast two i.e., one at the front and another at the rear of the crankshaft. More main bearings mean, less possibility of vibration and distortion of crankshaft of given size. To minimise the vibration in the engine crankshaft and flywheel are balanced separately and then often tested for balance when mounted together.

- The crankshaft transforms the linear motion of the pistons into rotational motion. It's connected to the pistons through connecting rods and is supported by bearings. The rotational energy generated by the crankshaft drives the vehicle's wheels.

7.Camshaft

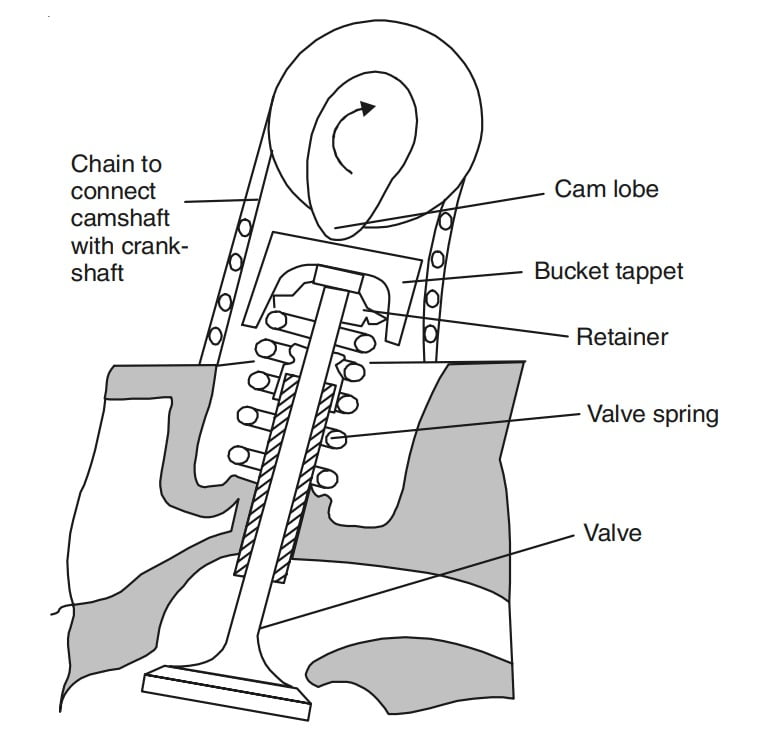

- It is a long straight piece of metal with a cam on it joining parts of machinery especially in a vehicle. It is responsible for opening/closing of valve.

- It carries one cam for each valve to be operated and valve lift is determined by the distance that the toe of the cam projects above the rounded base of the cam.

- The camshaft controls the opening and closing of the engine's valves. It's synchronized with the crankshaft through timing belts or chains and has lobes that push against the valves to actuate them at the right time during the engine's cycle.

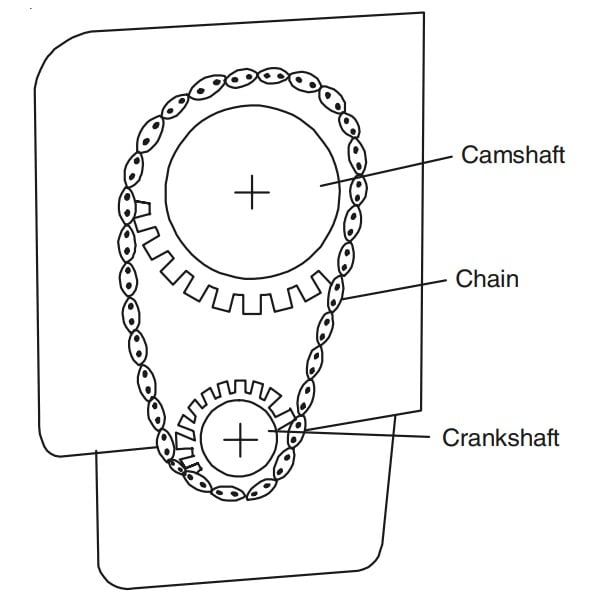

- The camshaft is driven by the crankshaft either by a pair of meshing gears or by means of a pair of timing sprockets connected by a chain. The camshaft rotates at `\left(\frac{1}{2}\right)` the speed of crankshaft as the valves open only once in complete cycle that require two crankshaft rotations in 4-stroke engine.

- The overhead camshaft (OHC) is a lately introduced modification in engine design.Earlier valves were operated with the help of camshaft located in the lower portion of engine. The push due to cam lobe was transferred to valve through push rods and rocker arms. The push rods and rocker arms resist the changing speed and direction due to their inertia.

- Sufficient force is needed to move them. Due to this, the push rod bends or flexes slightly. Bending and flexing also occurs in rocker arm but as the push rods are thin and long it is significant in them. At lower speed of engine the flexing of push rod has little affect but at high engined speed it causes a lag in valve action. This causes a limit to the engine speed while designing an engine.

- With the camshaft located in cylinder head, cam lobe directly pushes bucket tappet or rocker arm and necessity of push rod is eliminated (Fig. 7).

- There may be one overhead camshaft known as single overhead camshaft (SOHC) or two overhead camshaft (Double overhead camshaft, DOHC). In double overhead camshaft engines, one camshaft operates intake valves and other operates exhaust valves.

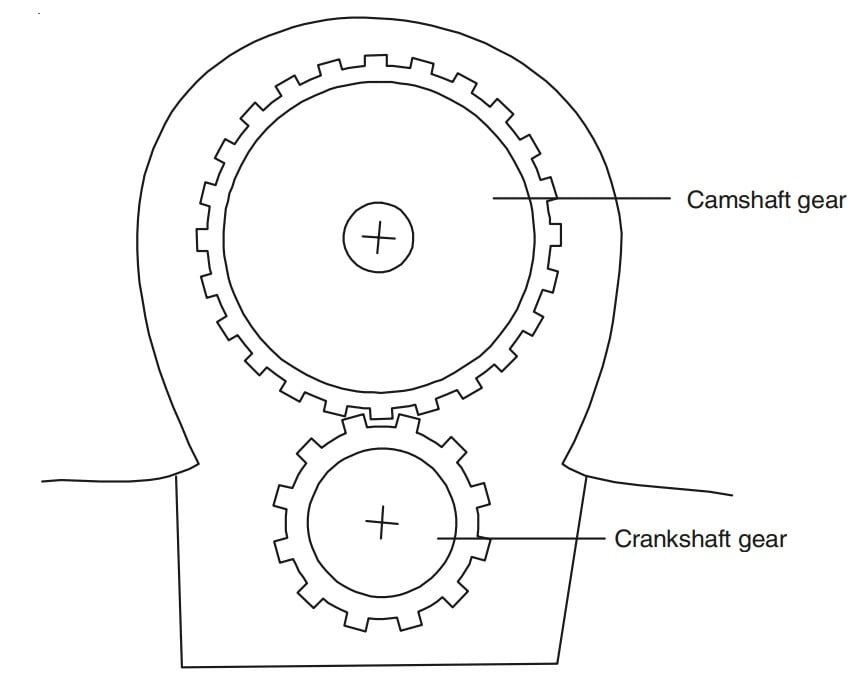

- To drive the camshaft either timing gears (Fig. 8) or sprockets and timing chain are used (Fig. 9). The use of sprocket and chain is preferred as these provide silent operation.

Conclusion

Understanding the components of an engine provides insight into how these complex devices operate. Vehicle performance and efficiency depend on every component, from the basic cylinder block design to complex systems like cooling and fuel injection. The next time you lift your car's hood, take a moment to take in the advanced engineering that drives your journey.