Introduction

Cement, which is crucial in civil engineering, strengthens the basis of modern construction. This article explores different aspects of cement such as its types, testing methods, unique characteristics, and wide range of uses in building structures.

Defination of cement

Cement, derived from limestone, clay, and minerals, is a powdery material that, through heating, forms a solid binder when combined with water. It plays a crucial role in construction, offering cohesion and durability to various building materials like concrete.

Types of Cement

- White Cement: Cement becomes white when manufacturers remove the coloring oxides of iron, manganese, and chromium. During production, they use oil fuel instead of coal for burning. Builders use white cement for floor finishes, plastering, and ornamental work. In swimming pools, they replace glazed tiles with white cement. It also helps fix marbles and glazed tiles.

- Coloured Cement: Manufacturers produce colored cements by intimately mixing pigments with ordinary cement. Chromium oxide gives a green color, while cobalt produces blue. Iron oxide in different proportions creates brown, red, or yellow shades. Adding manganese dioxide results in black or brown-colored cement. Builders use these cements to apply finishing touches to floors, walls, window sills, and roofs.

- Quick Setting Cement: Manufacturers produce quick setting cement by reducing the percentage of gypsum and adding a small amount of aluminium sulphate during the cement manufacturing process. They also grind the cement more finely to enhance its quick setting properties. This type of cement begins to set within 5 minutes after adding water and forms a hard mass within 30 minutes. Engineers use it to lay concrete under static or slowly running water.

- Rapid Hardening Cement: To produce this cement, manufacturers increase the lime content and burn the mixture at a high temperature during the manufacturing process. They also grind the cement very finely. Although it has the same initial and final setting times as ordinary Portland cement, it gains strength more quickly in the early days. This property allows for earlier removal of formwork and accelerates construction activities.

- Low Heat Cement: In mass concrete works like dam construction, the heat generated during cement hydration does not disperse easily, which may cause cracks. To prevent this, engineers prefer using low heat cement. This cement includes a low percentage (5%) of tricalcium aluminate (

C₃A) and a higher percentage (46%) of dicalcium silicate (C₂S). - Pozzulana Cement:Pozzolana, a volcanic powder found in Italy, also comes from processed shales and certain types of clay. This cement contains 10 to 30 percent pozzolana material. It resists sulphate action, releases less heat during setting, and offers a higher degree of water tightness. While it provides high tensile strength, its compressive strength remains low. Engineers use it for mass concrete works and sewage line construction.

- Expanding Cement: This cement expands as it sets because manufacturers add an expanding medium like sulpho aluminate and a stabilizing agent to ordinary cement. Builders use it to fill cracks in concrete structures.

- High Alumina Cement: Manufacturers produce this cement by calcining a mixture of lime and bauxite. It resists sulphate and acid attacks more effectively. It develops nearly full strength within 24 hours of adding water. Engineers use it for underwater works.

- Blast Furnace Cement: During pig iron production, slag forms as a waste product. Manufacturers produce this cement by grinding cement clinkers with about 60 to 65 percent slag. This cement shares most properties with ordinary cement but costs less because it uses waste material. It offers good durability but gains strength slowly, requiring a longer curing period.

- Acid Resistant Cement: Manufacturers produce this cement by adding acid-resistant aggregates such as quartz, quartzite, sodium silicate, or soluble glass. This composition gives the cement strong resistance to acids and water. Engineers commonly use it in the construction of chemical factories.

- Sulphate Resistant Cement: Manufacturers produce this cement by keeping the percentage of tricalcium aluminate (C₃A) below five percent in ordinary cement. Builders use it in structures exposed to alkaline conditions, such as canals and culverts.

- Fly Ash Blended Cement: Thermal stations generate fly ash as a byproduct. Since the particles are extremely fine, they disperse into the air and cause air pollution. To control and safely dispose of fly ash, thermal power stations spend significant amounts of money. One of the most effective disposal methods involves mixing fly ash with cement under controlled conditions, which also enhances certain properties of the cement. Nowadays, cement factories either produce fly ash in their own thermal stations or source it from others, then process it further to make it suitable for blending. Manufacturers typically blend 20 to 30% fly ash with cement.

Fly ash blended cements have superior quality of resistance to weathering action. The ultimate strength gained is the same as that with ordinary portland cement. However strength gained in the initial stage is slow. Birla plus, Birla star, A.C.C. Suraksha are some of the brand mame of blended cement.

Properties of Ordinary Portland Cement

- Tricalcium silicate 3 `C_aO.SiO_2;left(C_3Sright)` 40%

- Dicalcium silicate 2 `C_aO.SiO_2;left(C_2Sright)` 30%

- Tricalcium aluminate 3 `C_aO.Al_2O_3;left(C_3Aright)` 11%

- Tetracalcium aluminate 4 `C_aO.Al_2O_3;Fe_2O_3;left(C_3AFright)` 11%

There may be small quantities of impurifies present such as calcium oxide (CaO) and magnesium oxide (MgO).

When water contacts cement, `C_3A` reacts first and causes the initial set. It generates great amount of heat.`C_3S` hydrates early and develops strength in the first 28 days. It also generates heat. `C_2S` is the next to hydrate. It hydrates slowly and is responsible for increase in ultimate strength. `C_4A`F is comparatively inactive compound.

- Fineness

- Setting time

- Soundness

- Crushing strength

- Fineness: We measure fineness by calculating the percentage of weight retained after sieving the cement through a 90-micron sieve or by determining the surface area of cement in square centimeters per gram. According to IS code specifications, the weight retained on the sieve should not exceed 10 percent, and the specific surface area should be no less than 2250 `Cm^2` /gm.

- Setting time: The IS code specifies a minimum initial setting time of 30 minutes and a maximum final setting time of 600 minutes, provided testers follow the procedure outlined in IS 269-1967.

- Soundness: Once the concrete hardens, engineers must ensure that no volumetric changes occur. If the cement exhibits volumetric instability after hardening, they classify it as unsound. The IS code recommends using the Le Chatelier mould to test this property. At the end of the test, the indicator on the Le Chatelier mould should not expand more than 10 mm.

- Crushing strength: Technicians prepare mortar cubes using standard sand and test them in a compression testing machine according to IS code specifications. The minimum required strength is 16 N/mm² after 3 days and 22 N/mm² after 7 days of curing.

Physical Tests on Cement

(a) Soundness Test: Technicians conduct the test by performing a sieve analysis. They take 100 grams of cement and sieve it through IS Sieve No. 9 for fifteen minutes. Then, they weigh the residue left on the sieve, which should not exceed 10 percent of the sample’s weight.

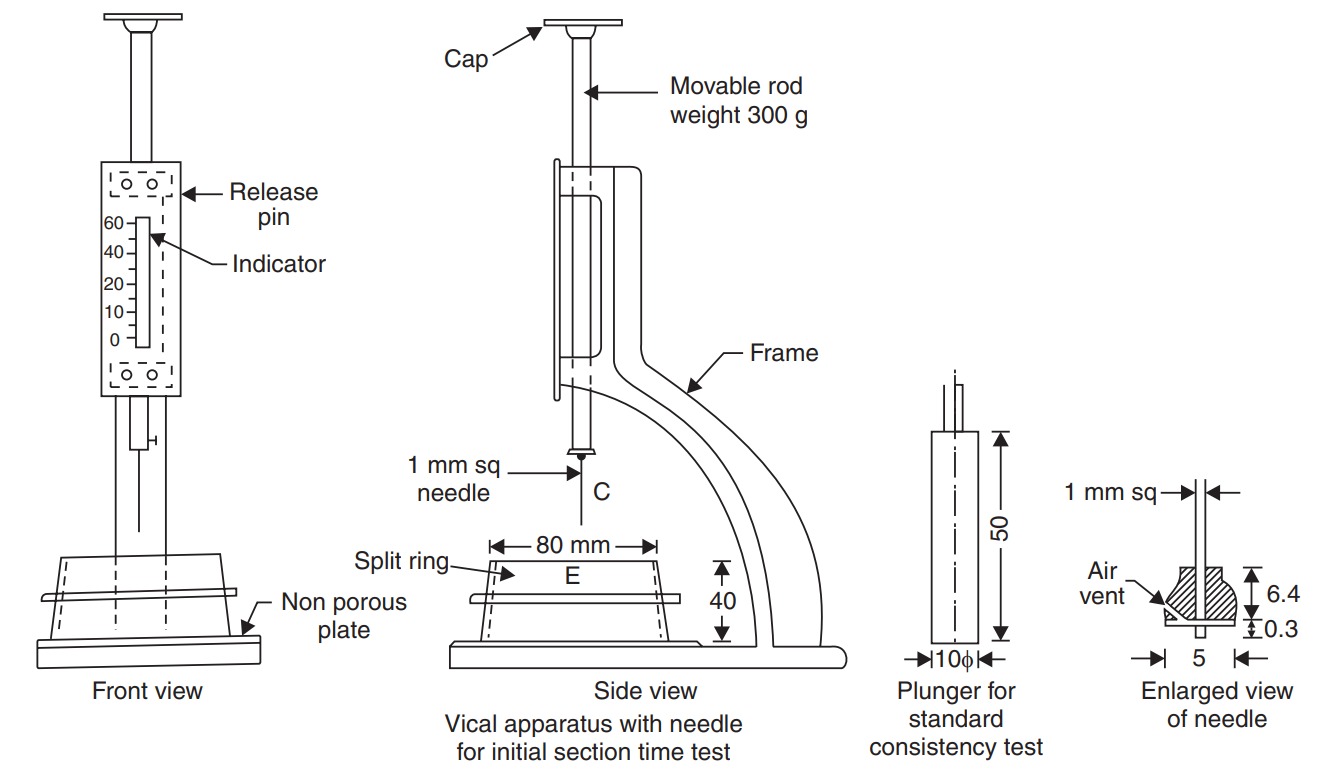

(b) Setting Time:Initial setting time and final setting time represent two crucial physical properties of cement. Initial setting time refers to the duration from the moment of adding water to when the cement begins to lose its plasticity. Final setting time marks the total time from water addition to the complete loss of plasticity. Engineers use the Vicat apparatus to determine these setting times [Ref. Fig. 5]. The Vicat apparatus includes a movable rod, to which the operator can attach any one of the three needles shown in the figure. An indicator connects to the movable rod to track penetration. The apparatus also includes a Vicat mould, shaped like a split cylinder.

Mix 300 g of cement with about 30% water to form a paste and place it in the Vicat mould on a non-porous plate. Lower the plunger until it touches the paste, and observe the penetration. If it reaches 5–7 mm from the bottom, the consistency is correct. If the penetration falls outside this range, adjust the water content and repeat the process until the needle reaches the desired depth. After establishing the standard consistency, start testing for initial and final setting times.

- Initial Setting Time:The tester thoroughly mixes 300 grams of cement with 0.85 times the water required for standard consistency. Then, they completely fill the Vicat mould with the paste and level the top surface. They fix a 1 mm² needle to the Vicat apparatus rod and gently place it over the paste. After releasing the needle, they observe its free penetration. Initially, the needle penetrates the paste fully. As time passes, the paste begins to lose its plasticity and resists penetration. When the needle can no longer penetrate beyond 5 to 7 mm from the bottom, the tester stops the experiment. They record the time elapsed from the moment of water addition to this point as the initial setting time.

- Final Setting Time: Replace the square needle with the annular collar and continue the experiment. Gently touch the surface of the paste with the needle, then allow it to move freely. Observe the moment when only the needle leaves a mark on the paste, without any impression from the annular ring. Note the time elapsed from the addition of water to this moment as the final setting time.

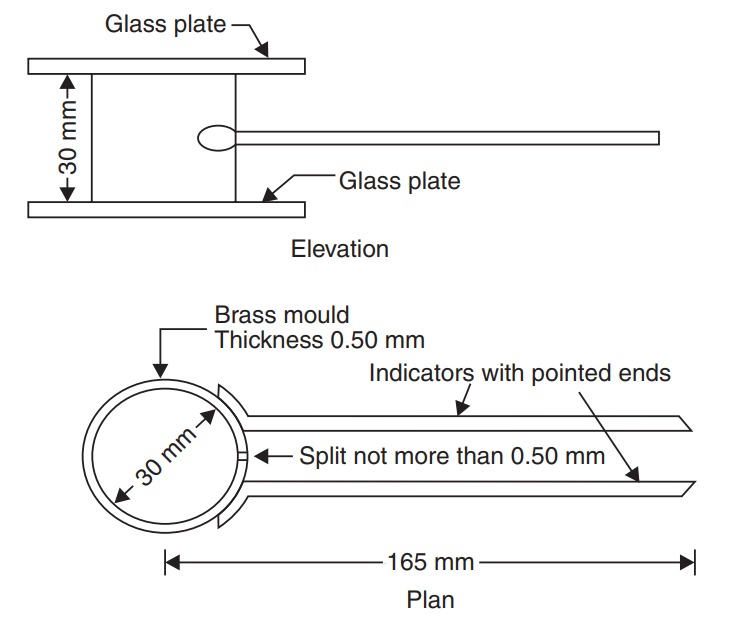

(c) Soundness Test: Use this test to determine the presence of free lime in cement, which is undesirable. Conduct the test with the Le Chatelier apparatus shown in Fig. 6. The apparatus includes a split brass mould with a 30 mm diameter and 30 mm height. Two indicators with pointed ends are attached on either side of the split. The pointed ends of the indicators extend 165 mm from the centre of the mould.

Fill a Le Chatelier mould, placed on a glass plate, with cement paste (using 0.78× standard consistency water). Cover with another glass plate, add a weight, and immerse in water at 24°C–50°C for 24 hours. Measure the distance between indicator points. Then, re-immerse the mould, heat to boiling in 30 minutes, and boil for 1 hour. After cooling, remeasure the distance. The difference shows cement expansion, which must not exceed 10 mm.

(d) Crushing Strength Test: To prepare the mortar, 200 g of cement is mixed with 600 g of standard sand (as per IS 650–1966). After one minute of dry mixing, distilled water equal to `frac P4+3` (where P is the water for standard consistency) is added. The mix is stirred for 3–4 minutes with a trowel. It is then placed in a 70.6 mm cube mould (Area 5000 `mm^2`) on a steel plate and compacted using a 25 mm standard rod, 20 times in 8 seconds. The mould is transferred to a vibrating table (12000 ± 400 vibrations/min). A hopper is attached, the mould is filled, vibrated for 2 minutes, then the hopper is removed. The surface is leveled, and after 24 ± 1 hour, the cube is demoulded and cured in clean water.

After specified period cubes are tested in compression testing machine, keeping the specimen on its level edges. Average of three cubes is reported as crushing strength. The compressive strength at the end of 3 days should not be less than 11.5 N/`mm^2` and that at the end of 7 days not less than 17.5 N/`mm^2`.

Uses of Cement

- Cement slurry is used for filling cracks in concrete structures.

- Cement mortar is used for masonry work, plastering and pointing.

- Builders use cement concrete to construct various structures like buildings, bridges, water tanks, tunnels, docks, and harbours.

- Cement is used to manufacture lamp posts, telephone posts, railway sleepers, piles etc.

- For manufacturing cement pipes, garden seats, dust bins, flower pots etc. cement is commonly used.

- It is useful for the construction of roads, footpaths, courts for various sports etc.

Conclusion

Cement, with its various kinds, strict examination methods, distinct characteristics, and flexible uses, remains crucial in contemporary building. With technological advancement and sustainability efforts, cement progresses to provide the strength, lastingness, and versatility needed for constructing resilient structures in our urban spaces.