Introduction

Each and every car comes with an engine. This vital part is what produces the force needed to get the vehicle moving. The sheer variety present in modern engine configurations is a testament to the advancements that have reshaped automotive technology over time. A core grasp of these varying engine designs is essential, not just for seasoned professionals, but also for hobbyists and anyone captivated by the mechanics of a vehicle.The aim of this article is to provide a comprehensive overview of the numerous categories of car engines, focusing on their operational characteristics, advantages they offer, and typical applications.

Classification of automobile engines

Automobile engines are classified on the following basis.

1.Number of Cylinders

Engines come in two primary configurations: those with a single cylinder, and those with multiple cylinders. The defining characteristic of a single-cylinder engine is, quite simply, a single cylinder. In contrast, multi-cylinder engines – the terminology itself is descriptive – incorporate a plurality of cylinders. Regardless of how many cylinders an engine has, all pistons within those cylinders connect to a single crankshaft. Consequently, engines can be categorized as:

1.Single cylinder engine

- Air-cooled single cylinder produces its combustion only from one cylinder.

- Simplicity is their forte; their build and architecture are notably less complex than that of engines featuring numerous cylinders.

- One might reasonably assume their application spans various small power sources; consider, for example, the engine driving a motorcycle, or those commonly found in lawn mowers, and other comparable uses.

- Single cylinder motors generally prove to be lighter, more compact, and cheaper to buy than multi-cylinder engines.

- Such engines in general are weaker and less torquey than multi-cylinder engines of the same size, even with the best tuning.

2.Multi cylinder engine

- A multi-cylinder engine has more than one cylinder, placed in the different layouts, like the inline, V-layout, flat, and radial.

- These mechanical workforces are amenable to configuration using either four, six, eight, or potentially greater numbers of cylinders. The particular cylinder arrangement adopted is contingent upon the intended use case as well as the target operational characteristics.

- Engines featuring multiple pistons see broad usage across various sectors. Cars, lorries, aircraft, luxury sailing vessels, and high-capacity power generators all frequently utilize them.

- They offer efficient economy of operation, have higher kW output, and better torque as compared to engines with a single cylinder.

- Because multiple cylinders and more parts make them that much convoluted, multi-cylinder engines are bulkier, larger and therefore often pricier.

2.Cylinder Arrangement

1.In-line Cylinder Engine

- An inline cylinder engine, frequently identified as a straight or inline engine, constitutes a distinct arrangement for internal combustion engines. This engine design features cylinders deliberately arranged in a straight, linear manner. They are situated one after another along the crankcase. Inside each cylinder resides a single piston, generally linked to a unified crankshaft to ensure coordinated movement.

- The in-Line cylinder engine is a multi-cylinder engine, with all the cylinders arranged in one straight line. Each cylinder has an independent crank.

- The architecture of an inline cylinder engine features cylinders positioned in a single file. This alignment can manifest either upright or sideways, the specific orientation governed by the engine's engineering. To illustrate, a common example is the inline-four, which showcases four cylinders meticulously organized in a straight sequence.

2.V Cylinder Engine

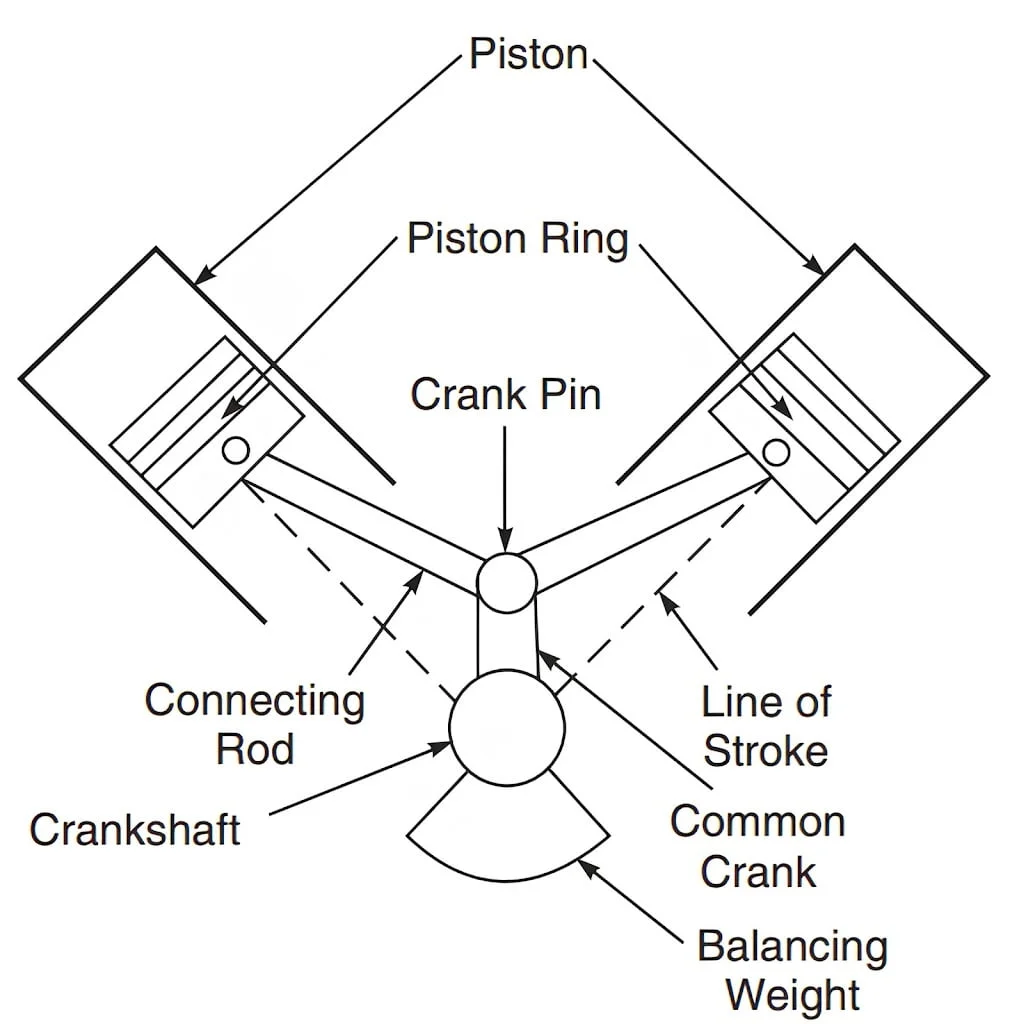

- A V-cylinder engine, often referred to as a V-engine, represents an internal combustion engine design. This design places cylinders in a V shape, observable from either the front or the back of the engine. The setup contributes to a more space-efficient structure when compared to in-line engines, and further offers beneficial balance and operational output. The subsequent details outline notable aspects of the V-cylinder engine arrangement.

- Within a V-type engine, the cylinders are positioned in a configuration of two banks, which intersect to create the visual of a V. The angular measure between these banks is variable; typical instances include a span from 60 degrees to 90 degrees. Despite this, various specific engine architectures utilize angles beyond this common range.

Below there is a some common types of V cylinder engine.

- This configuration has six cylinders arranged in two rows forming a V shape. `V_6` engines are widely used in passenger cars, SUVs, and some trucks due to their balance of power and relatively compact size.

- Boasting substantial power and optimal performance, the `V_8` engine configuration employs eight cylinders arrayed in a V formation. This design is a staple in the automotive world, frequently found powering high-performance sports cars, upscale luxury automobiles, and heavy-duty trucks.The `V_8` engine architecture utilizes a setup comprising two engine blocks, positioned at a ninety-degree angle relative to one another. Each of these blocks is equipped with four individual cylinders.

- The `V_10` and `V_12` arrangements remain prevalent, finding homes primarily in the domain of elite sports cars, supercars, and high-end luxury automobiles. The inherent appeal stems from their ability to deliver elevated levels of power and refinement, achievable through the employment of a greater number of cylinders.The subsequent illustration provides a visual depiction of a typical V-engine layout.

Figure 1

3.Valve Arrangement in Cylinder Head Assembly

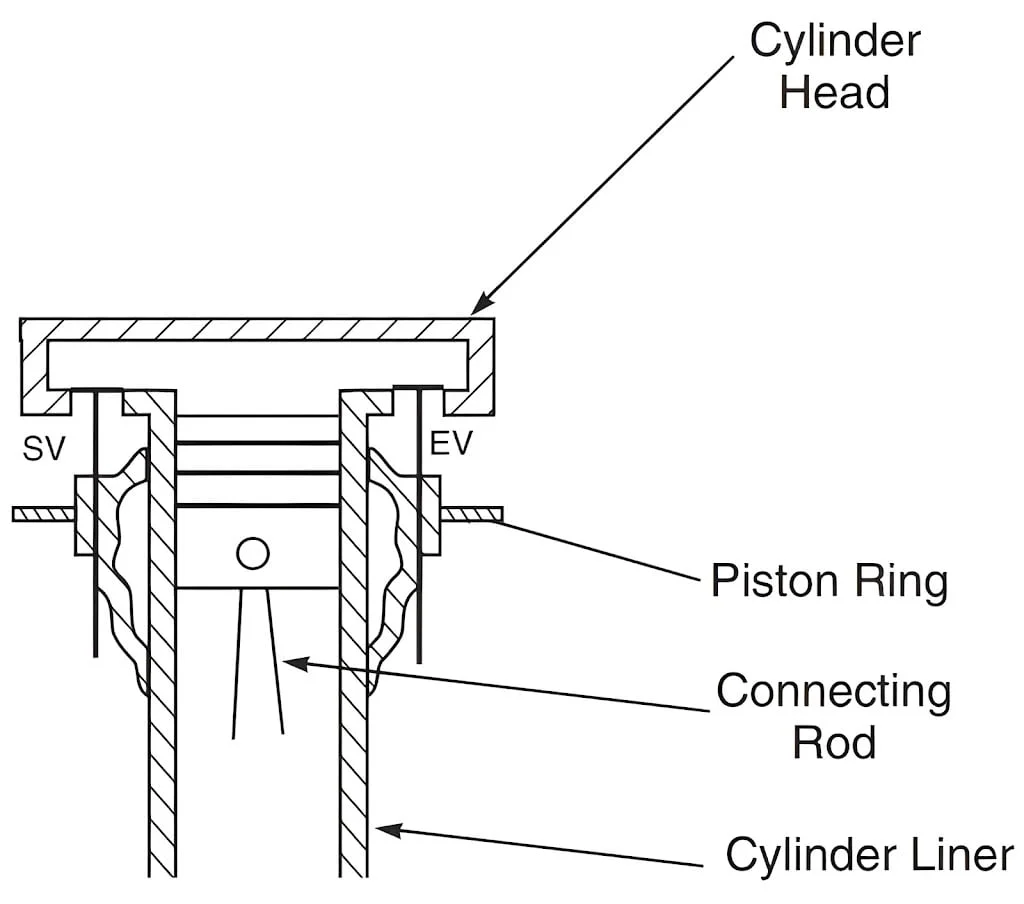

1.T-head Engine

- The T-Head engine's valve layout provides its most striking feature. More specifically, intake valves always occupy one side of the cylinder's expanse.Conversely, the exhaust valves are always located on the opposite flank.Visualizing this setup from a top-down view reveals a distinct "T" figure. The fundamental design of the engine gets its moniker from this specific formation. In older engine variants, this layout, where valves are oriented at a perpendicular angle relative to the cylinders, is a key characteristic.

- Automakers embraced this configuration early on. The design’s simplicity resulted in an engine that was reasonably straightforward to maintain. Despite this, airflow wasn’t as optimal compared to modern builds. Also, the combustion procedure was less efficient.

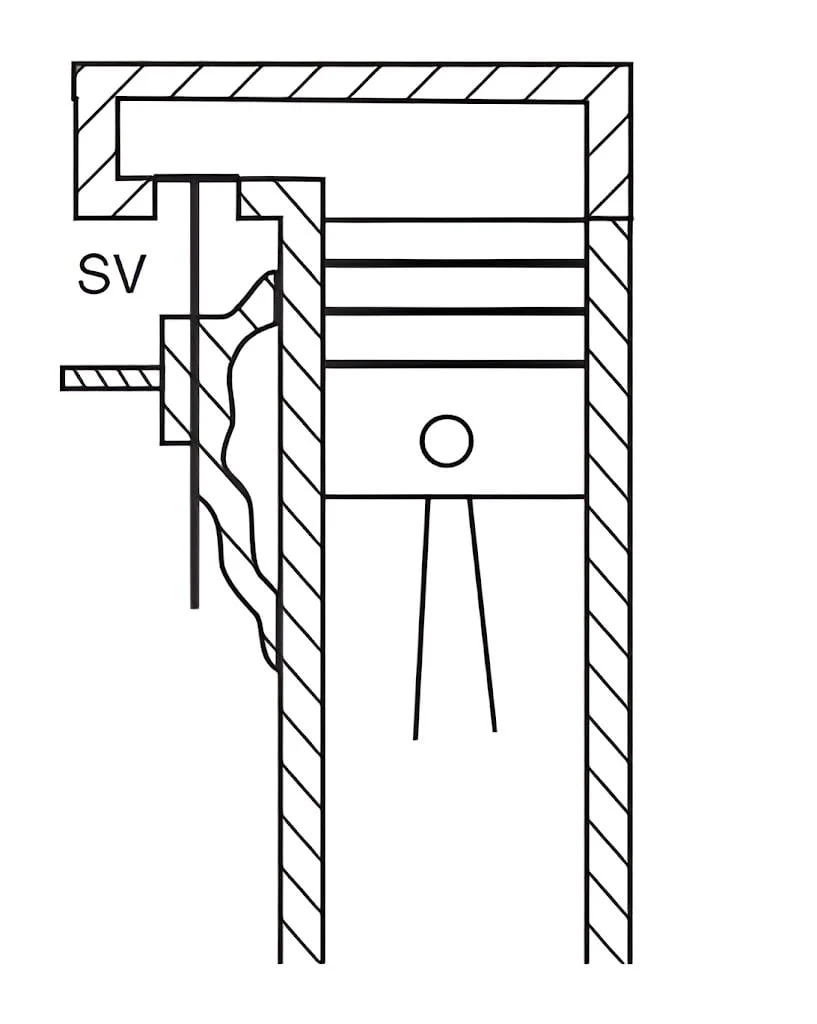

- In the T-head engine the valves are arranged as shown in Fig. 2. The suction valve (SV) and the exhaust valve (EV) are on the cylinder block in opposite directions.

Figure 2

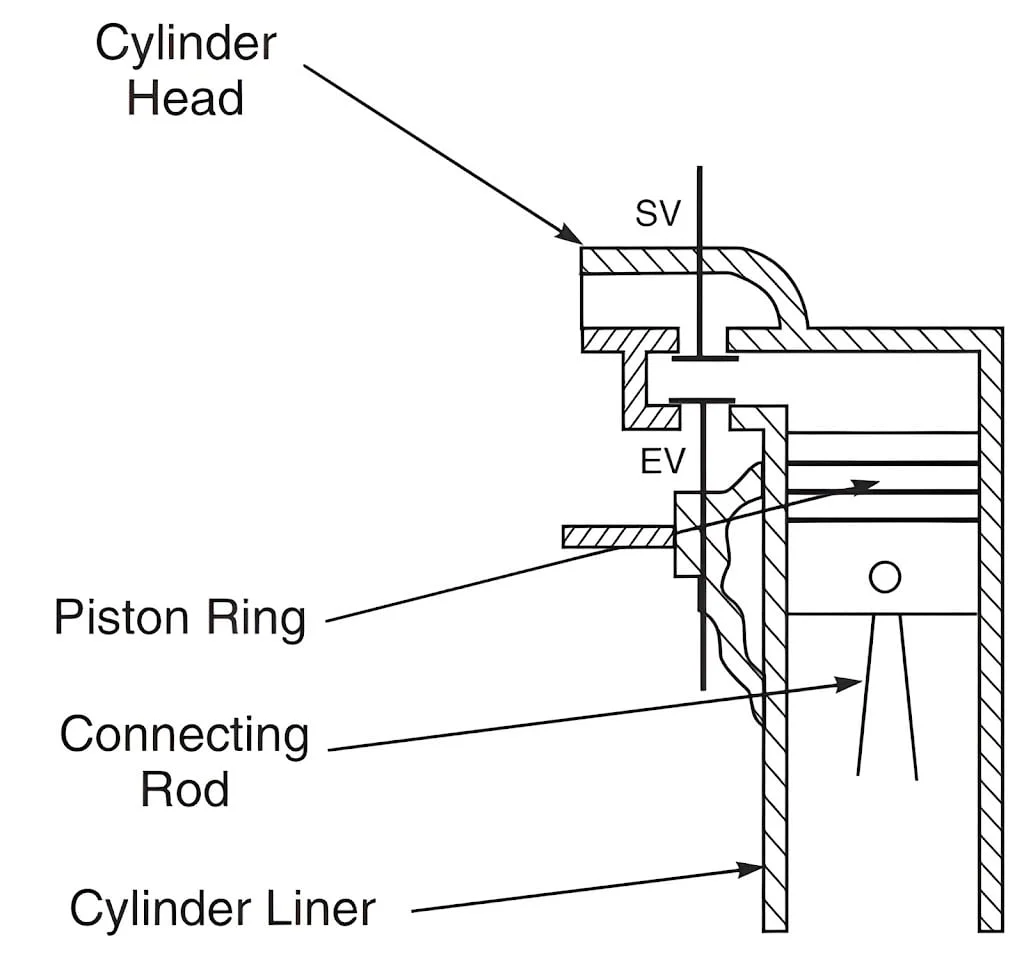

2.F-head Engine

- These engines are OHV as well as the OHC engines. Intake valves are overhead in cylinder head and exhaust valves are in the engine block (overhead valve).FA integer engines provide more air flow and combustion efficiency than T integer, but limited by exhaust valves in engine block, so cannot influence exhaust flow.

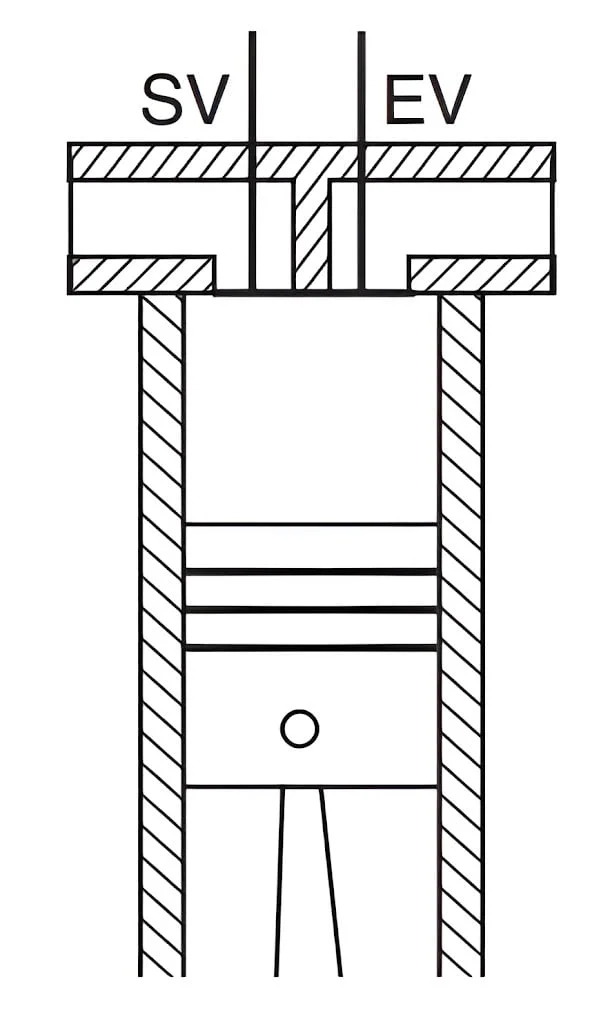

- In the F-head engine one valve is in the cylinder block and the other valve is in the cylinder head as shown in Fig. 3.

Figure 3

3.L-head Engine

- L Head engines, also known as flathead engines, have both intake and exhaust valves located in the engine block beside the cylinders, with the valves operated by a single camshaft located in the block.L Head engines were popular in early automotive designs due to their simplicity and compact size. However, they are less common in modern engines due to limitations in airflow and combustion efficiency.Simple design, compact size.Limited airflow and combustion efficiency compared to overhead valve designs.

- The L-head engine's design, depicted in Figure 4, features both the intake and exhaust valves positioned adjacent to each other within the cylinder block.

Figure 4

4.I-head Engine

- Valves are situated in one of two states: intake or exhaust. They're arranged in a row, known as an inline configuration. Cylinder heads of I Head engines handle each cylinder with a single, unified head, a design frequently associated with inline arrangements.This design deliver the desired intake and exhaust flow are superior to those with T and F Head designs. Manual operation of the device may require complexities such as that of valve arrangements hence maintenance of the device may be more involved.

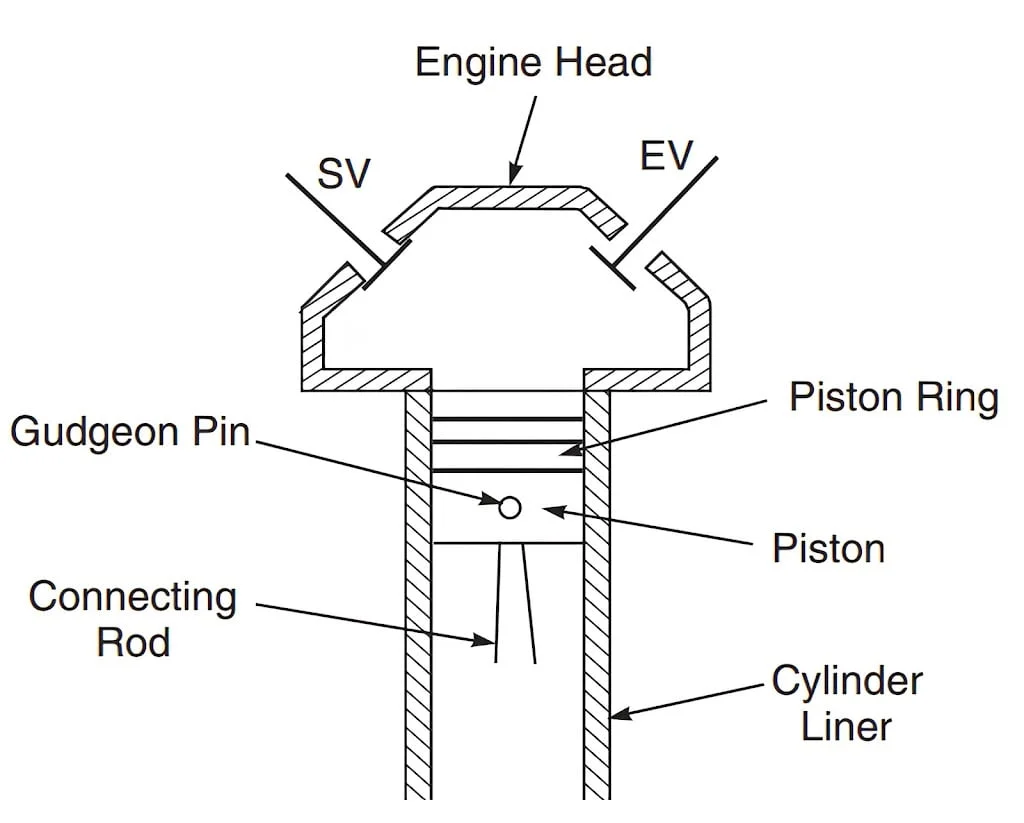

- In the I-head engine the suction and exhaust valves are arranged in the cylinder head as shown in Fig. 5.

Figure 5

5.Overhead Engine

- In overhead designs, valves find their home, installed directly inside the cylinder head. Two main pathways exist to control the opening and closing of these valves. The first involves pushrods in tandem with rocker arms - a setup typically identified as OHV (Overhead Valve). A second alternative centers around camshafts, employed to make direct valve actuation possible; this is a hallmark of OHC (Overhead Camshaft) or DOHC (Dual Overhead Camshaft) arrangements. At its core, the concept of overhead engines turns on their sophisticated build. The defining characteristic lies in the valves' location: they're situated atop the cylinders. This strategic valve placement is far from arbitrary; it plays a crucial role in optimizing the flow dynamics, governing both the influx and the efflux of gases.

- The cylinder head, in the overhead engine configuration, is the location of both the intake and exhaust valves. Its typical shape, as illustrated in Figure 6, is hemispherical. The primary distinction lies in the mechanics of valve operation. In an I-head arrangement, pushrods are employed to actuate the valves. Conversely, overhead valve designs rely on camshafts, positioned directly within the cylinder head, to open and close the valves.

Figure 6

6.Air-cooled Engines

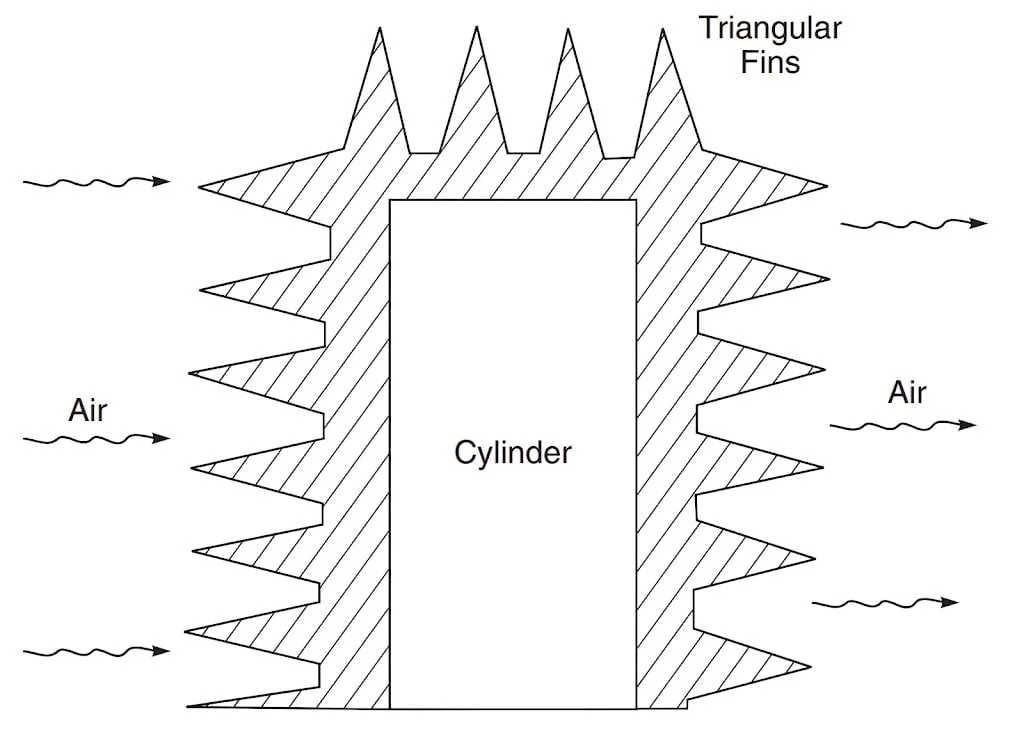

- Engines that rely on air cooling work by exploiting the flow of air to draw off heat, doing away with the need for a distinct cooling mechanism, such as a radiator or fluid coolant.These engines use cooling fins, affixed to the outer portions of the engine's block and cylinder heads. These fins are designed to amplify the surface area, therefore improving the efficiency of heat dissipation. Their construction is considerably simpler when placed next to water-cooled engines, with fewer components and specifically lacking components such as water pumps, radiators, and coolant lines.

- Because they lack liquid cooling apparatus, engines cooled by air usually weigh less, which makes them a good fit for purposes where mass is a critical factor. This particular engine design finds common application within the realm of diminutive machinery. You'll find it powering motorcycles, along with light aircraft models, various landscaping implements, and also portable power generators.

- Engines cooled by air employ fins to release warmth into the atmosphere around them. The fins, designed in a triangular shape, serve to increase the surface area from which heat can escape. Constructed from aluminum, these parts take advantage of this material's excellent ability to conduct heat.Air-cooled engines typically operate at elevated temperatures, given that air isn't an effective thermal conductor. An illustration of an air-cooled engine is presented in Figure 7.

Figure 7

7.Water-cooled Engines

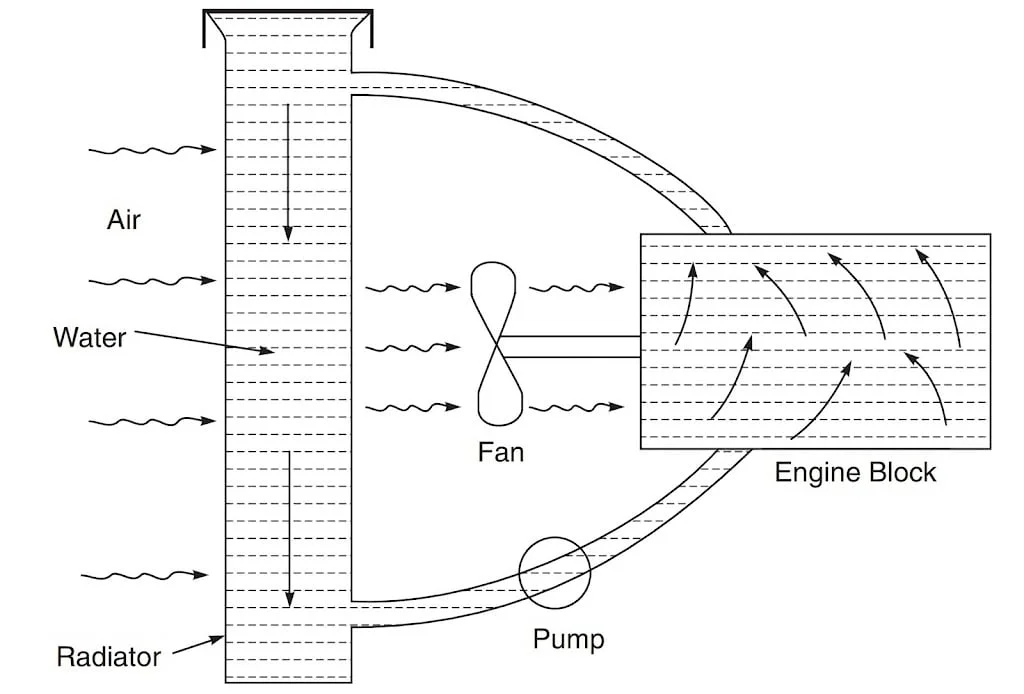

- Water-cooled engines use a liquid coolant (usually a mixture of water and antifreeze) circulated through a cooling system to regulate engine temperature.Water-cooled engines have a radiator, water pump, coolant hoses, and a thermostat to regulate coolant flow and engine temperature.The liquid coolant can absorb more heat compared to air, providing efficient cooling even under heavy loads or in hot climates.

- Engines cooled by water exhibit a greater degree of thermal stability, a factor vital to their efficiency and prolonged lifespan. Such engines are frequently found in cars, lorries, heavy-duty equipment, and performance-focused automobiles.

- Water-cooled engines require circulation of water. All automobile engines,which are water-cooled,are fitted with radiators as shown in Fig. 8. The radiator offers resistance to the flow of air through the passages in between the small diameter tubes carrying hot water.

- Therefore an induced draught fan is provided at the back of the radiator. This fan creates the pressure difference required to get an increased flow of air. Similarly, to get pressure difference and to overcome the resistance in the water flow at the jackets of the engine, a water pump is provided which draws water from the radiator and forces it into the water jacket of the engine.

- The water's temperature is under careful control, with the primary goal of avoiding any increase, since going beyond a threshold encourages the formation of scale. This scale, through its gradual build-up, subsequently triggers localized overheating.The reason behind this lies in the scale's interference with efficient cooling; it effectively acts as an insulating layer. The existence of such spot-specific overheating presents a genuine explosion risk, capable of inflicting significant damage on key engine parts.

Figure 8

8.Gasoline Engine

- A gasoline engine also known as a petrol engine operates by igniting a mixture of gasoline and air to produce power. Gasoline engines use spark plugs to ignite the air-fuel mixture in the combustion chamber.They require a fuel delivery system,typically consisting of a fuel pump,fuel injectors (in modern engines) and a fuel tank.Gasoline engines usually have a lower compression ratio compared to diesel engines,requiring a spark to initiate combustion.

- Gasoline engines tend to produce less noise and vibration compared to diesel engines of similar size and power output.

- The internal combustion engine, commonly found in cars, utilizes gasoline – often referred to as petrol – as its power source. Before entering the cylinder, this fuel undergoes a mixing process with air. Once inside, and following compression, an electrical spark, generated by a spark plug, is employed to ignite the compressed fuel-air blend.

9.Diesel Engine

- A diesel motor works through the combustion of diesel and air, both compressed inside a cylinder within the engine. This compression then provides enough warmth to set off the mixture of fuel.The core of how a diesel engine operates rests on compressing air inside a cylinder, which drives temperatures upward to a certain point. After this, the fuel itself, diesel, gets pumped in. The injected fuel then combusts instantaneously as a result of the heat; no spark plugs are necessary.The unique capability of a diesel engine resides in attaining significantly high compression ratios. It is this process that makes igniting fuel possible without the requirement of spark plugs.

- Diesel fuel injectors serve the critical function of precisely delivering fuel into the combustion chamber of an engine.

These power plants are renowned for the substantial torque they generate, a trait that makes them ideal for demanding applications. They find wide usage, encompassing areas like commercial transport, mass transit systems, and industrial machinery. - Diesel engines tend to be more fuel-efficient than gasoline engines, especially in applications with constant or high loads.

10.Gas Engine

- Combustible gases serve as the fuel within a gas engine. Such engines are not frequently found in cars.A gas engine, sometimes referred to as a methane engine or a natural gas engine, primarily utilizes natural gas for its operation.Gas engines function by utilizing natural gas. This gas mostly consists of methane, potentially with other hydrocarbons present as well.

- They require a fuel delivery system designed for natural gas, including gas storage tanks, regulators, and fuel injectors.Gas engines may use spark ignition (similar to gasoline engines) or compression ignition (similar to diesel engines) depending on the design and application.

- Natural gas is considered a cleaner-burning fuel compared to gasoline or diesel, resulting in lower emissions of pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM).

Use of engine

- Two-stroke cycle gasoline engines with petrol lubrication are used in light duty automobiles like mopeds, scooters etc.

- Two-stroke cycle diesel engines with pressure lubrication are used in medium duty automobiles like tempos etc.

- Four-stroke cycle gasoline and diesel engines with splash and pressure lubrication are used in heavy duty automobiles like trucks, buses, delivery vans etc.

- Cars are provided with four-stroke gasoline engines with splash and pressure lubrication systems.

- The inline engine is vertical, i.e. the stroke of the pistons is vertical. Such inline vertical engines are used in cars, buses, trucks etc.

- V-engines have cylinders at 90° and are used in heavy duty motor cycles, which are designed for long run.

- Single-cylinder horizontal engines are used in scooters and mopeds. This engine is so located that the cylinder head is towards the front of the scooter or moped.

Conclusion

The automotive sector has been dynamically developing, and the innovations aimed at the engines have become more and more energy-efficient, powerful, and environmentally friendly. Knowledge of different automobile engines types is obligatory for engineers, manufacturers and consumers as well at we work towards a cleaner and more efficient transportation system of the future. Whether it's the conventional gasoline engine, the novel system of hybrid technology, or the pollution-free electric motor, every variant of an engine type comes together to form the enormous field of automobile engineering.