Introduction

Cars, the wonders of contemporary engineering, are complex mechanisms consisting of various components cooperating to offer a dependable form of travel. In this article, we will delve into the inner workings, examining the various vital parts that make up a car. From the robust engine to the detailed interior, each element is crucial for a seamless and secure driving experience.

Parts of an automobile

An automobile has several numbers of component. But there are four basic components.These are:

- The Chassis

- The Engine

- The Transmission System

- The Body

- Lubrication System

- Cooling System

- Fuel System

- Ignition System

- Electrical System

- Suspension System

- Power Train

- Clutch

- Drive Shaft

- Differential

- Axles

- Wheels

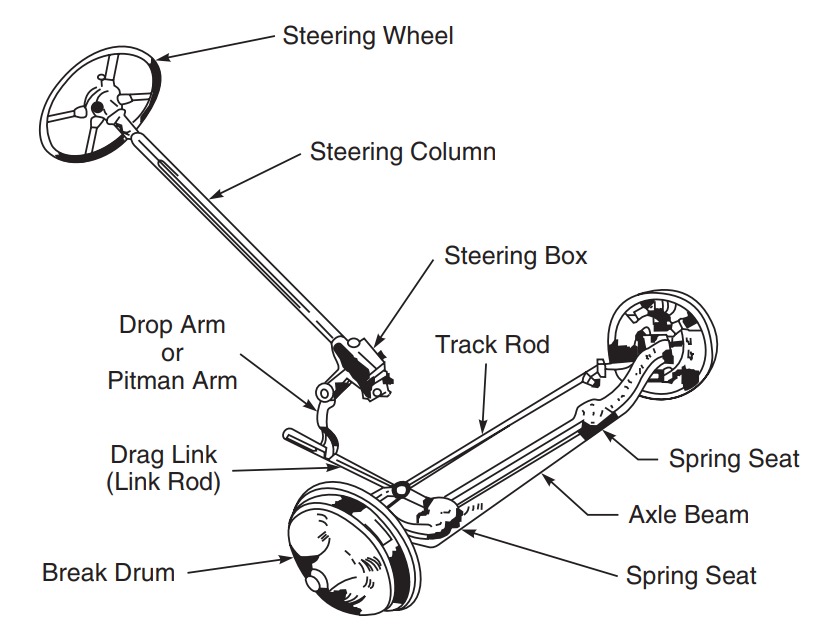

- Steering System

- Braking System

- Accessories

Apart from these four basic components, there are controls and auxiliaries. The controls are meant for controlling the movement of vehicle. The auxiliaries are additional components meant for providing comfort to the user of the automobile.

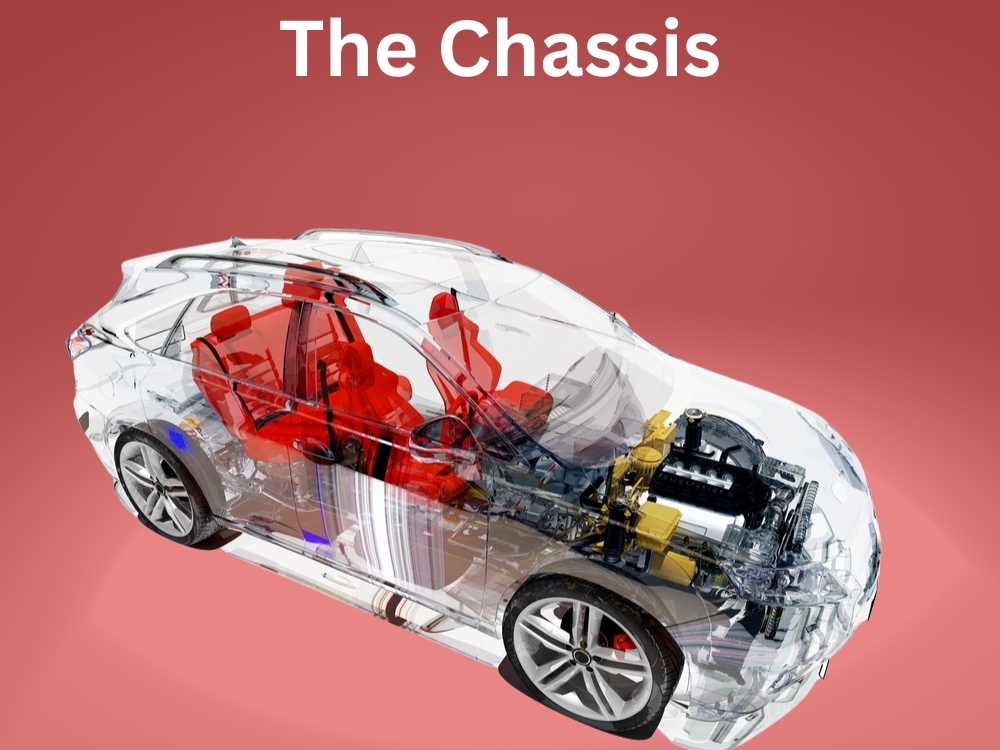

1.The Chassis

The chassis of an automobile incorporates all the major assemblies consisting of engine,components of transmission system such as clutch, gear box, propeller shaft, axles, control system such as brakes and steering and suspension system of the vehicle. In other words,it is the vehicle without its body.

The chassis of an automobile has the frame, suspension system, axles and wheel as the main components (Shown in Fig 1). The frame could be in the form of conventional chassis or unit construction may be adopted. In conventional chassis frame, the frame forms the main skeleton of vehicle. It supports engine, power transmission and car body. The frame is supported on wheels and axles through springs.

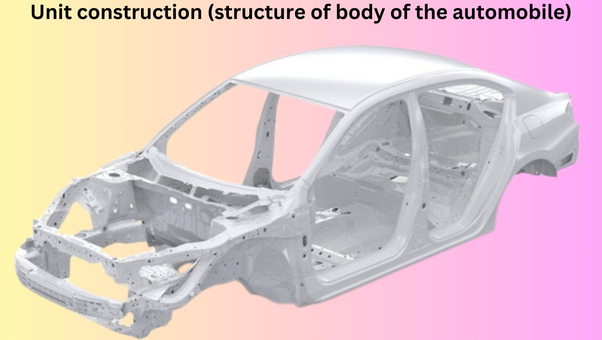

The frame carries the weight of the vehicle and passengers, withstands engine, transmission, accelerating and braking torques.It also withstands the centrifugal forces while cornering and takes up stresses due to rise and fall of axles. In unit construction type there is no frame (Shown in Fig 2).

The structure of body of the automobile is first formed and then different components such as engine, transmission system and other parts are placed at suitable places in the body structure. The transmission system itself consists of a number of parts such as clutch assembly, gear box, propeller shaft, differential and axles. The other parts include the interior details which are utilized by the passengers and driver of the vehicle. Through suitable designing, the parts are so arranged that they provide maximum comfort and make journeys in the automobile enjoyable.

The other part of chassis are suspension system, axles and wheel. The suspension system absorbs the vibrations due to up and down movement of wheels. Springs and shock absorbers connecting the frame and the axle perform this function. The springs can be leaf spring, coil spring or torsion bar. Even rubber or air can form the material of springs. The wheels of the vehicle can be suspended independently on springs or on spring suspended axles.

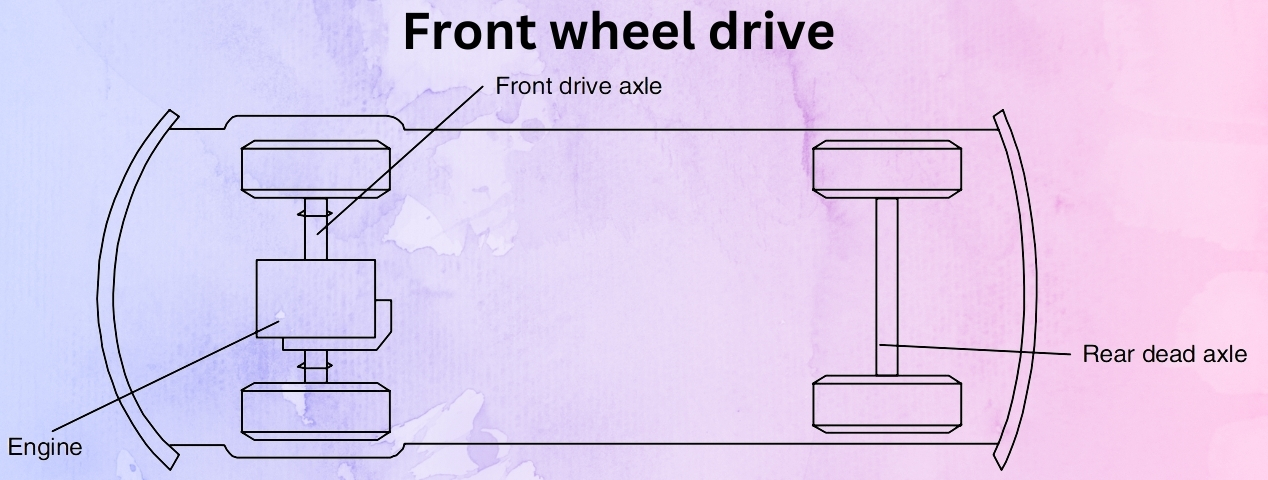

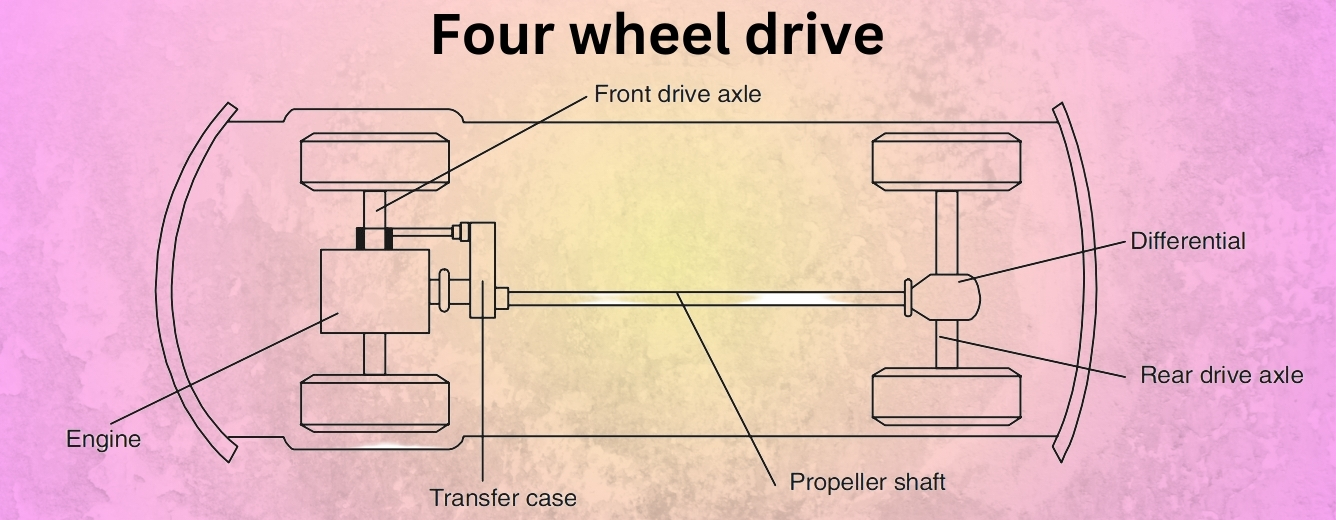

The axle may be ‘live’ if power from the engine is transmitted to it. It may be a ‘dead’ axle if no power is supplied to it and it is just supporting the weight of the vehicle. In ‘four wheel drive’, the power is supplied to both the axles and therefore both the axles are ‘live’.In addition to providing support to the weight of the vehicle, the axle also resists the stresses due to braking and driving torque.

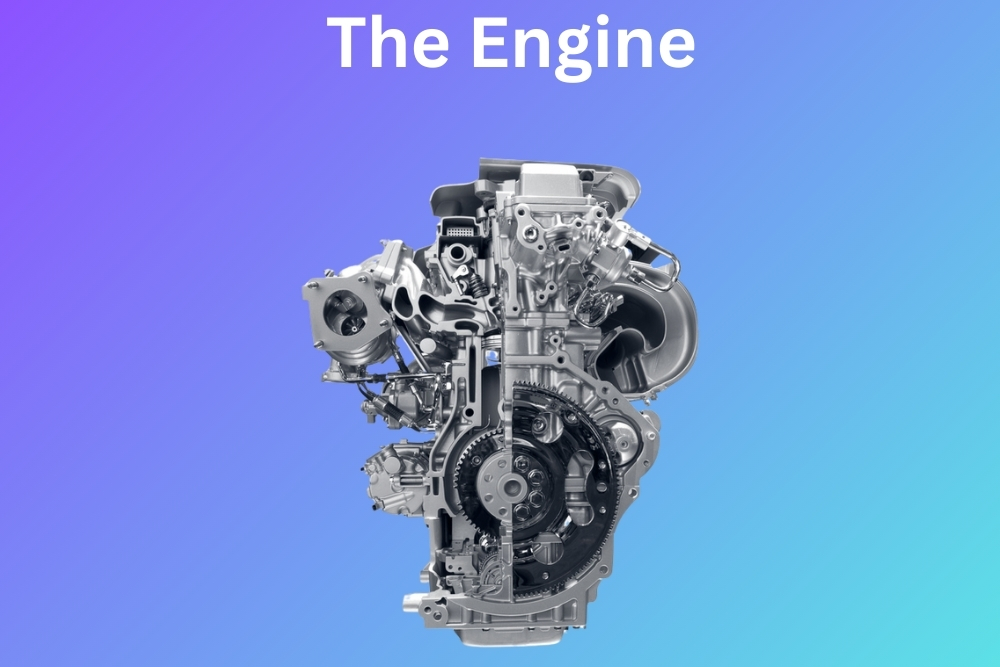

The Engine

The engine is the source of motive power to an automobile. Obviously it is very important part of the automobile because in the absence of engine the automobile may not move at all and its basic function of transporting passengers or goods would be defeated. The power of the engine determines the working of the automobile. In the same manner, the efficiency of engine determines the efficiency of automobile.

The engine, now-a-days, is invariably an internal combustion engine. This may be spark ignition engine consuming petrol as fuel. Alternatively, it could be a compression ignition engine using diesel as fuel.

The engines used are multi-cylinder engines. A single cylinder engine, though capable of providing the desired power may become very heavy and therefore may be unsuitable. In multi-cylinder engine each cylinder handling smaller amount of power may keep engine light in weight.

In an internal combustion engine, not all the heat generated by fuel combustion is converted into useful work. A significant portion increases the engine's temperature, which can lead to overheating if not properly managed. To control this, the engine uses a cooling system that removes excess heat using a coolant. This coolant may be air or water, depending on the engine design resulting in air-cooled or water-cooled engines. In modern engines, specially formulated chemical coolants are also used. These coolants have enhanced thermal properties and remain stable and effective over longer periods, improving overall cooling efficiency.

These chemicals are being used as coolants and these do not require frequent replacement. Apart from their longer life they are more efficient also. Similarly lubrication is another aspect to be taken care of in an engine requiring periodic attention from the user. The moving parts in an engine need regular lubrication to reduce unwanted friction. The chemistry of lubricant is now highly developed. There is standard rating for lubricants and for every purpose a specific lubricant is available.

The Transmission System

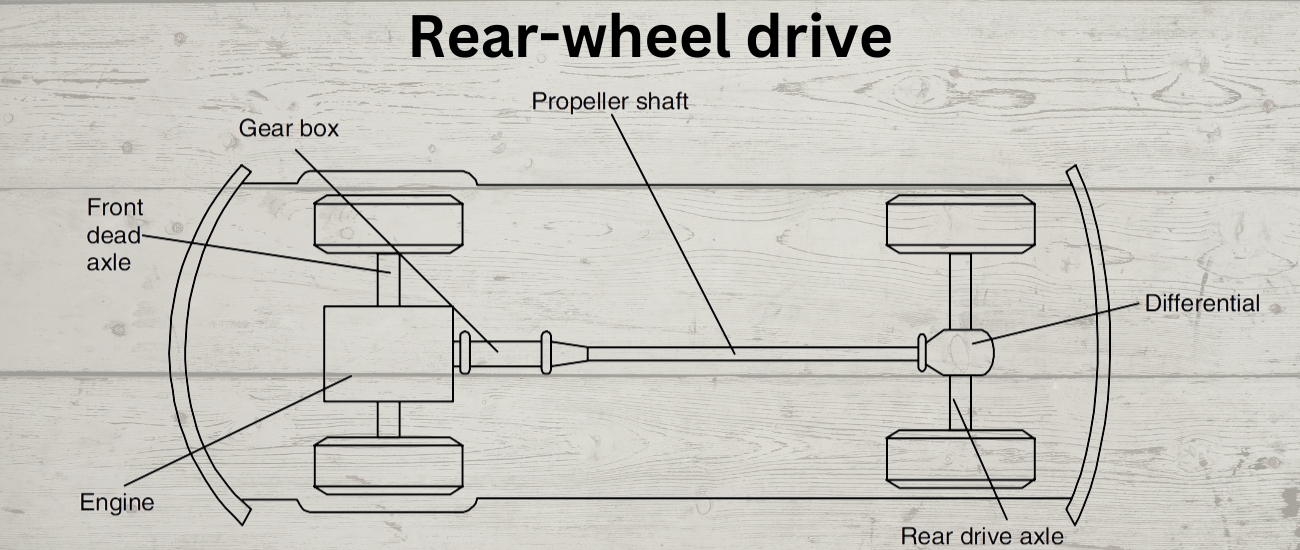

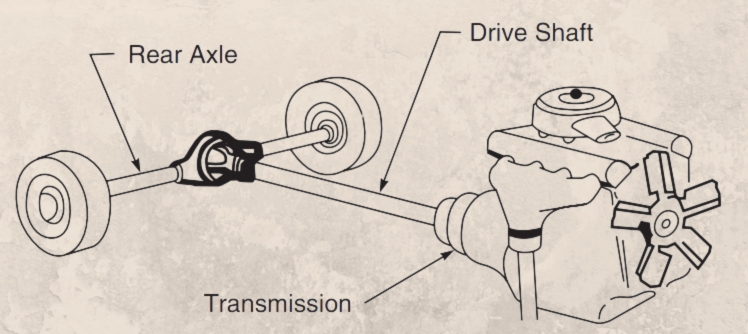

The transmission system transfers the power generated by the engine to the road wheels. The engine produces rotary motion through the crankshaft, and this motion must reach the wheels to drive the vehicle. The system includes several key components: the clutch, gearbox, propeller shaft, differential, and live axle. The road wheels connect at the ends of the axle. Each component in the transmission system has a specific role in ensuring the smooth and efficient delivery of power to the wheels.

The clutch, a part of the transmission system, connects directly to the crankshaft. It enables the rotary motion of one shaft to be transmitted to another as needed. When the engine starts, it should not immediately engage the road wheels—these should remain stationary until the driver chooses to move the vehicle. Additionally, the power transfer must occur smoothly to avoid passenger discomfort and to protect the vehicle’s components. In goods transport vehicles, smooth engagement is especially important to prevent damage to the cargo.

Gear box is the component of transmission system next to clutch. It has got gear train and it provides different gear ratios. These ratios determine the rotary speed of output shaft from gear box. The torque transmitted to the road wheels give rise to a propulsive force (or tractive effort) between these and the road. When starting from rest large tractive effort is required.

This makes essential the introduction of considerable ‘leverage’ between engine and the wheels so that torque from engine, which is almost constant, produces large tractive effort. This ‘leverage’ is provided by the gear box. Different gear ratios available in the gear box can provide the required tractive effort to overcome the resistance faced by the automobile under different conditions.

The propeller shaft transmits the output from the gearbox to the axle. This axle can be at the rear, the front, or in some cases, both the rear and front axles receive output from the gearbox (as shown in Figures 4, 5, and 6). The gearbox produces rotary motion, which the propeller shaft transfers directly to the axle.

The differential is the next component in the transmission system. It receives motion from the propeller shaft and turns it through 90 degrees using a pinion and a gear, aligning it with the axle. This change in direction is necessary because the axle lies perpendicular to the propeller shaft. The differential also adjusts wheel speeds when the vehicle takes a turn by reducing the speed of the inner wheels and increasing the speed of the outer wheels by the same amount.

On a curved path, the outer wheels must travel along a circle with a larger radius than the inner wheels. Therefore, the outer wheels cover a greater distance than the inner wheels.

Since the automobile moves as a single unit, all four wheels must rotate together. To achieve this, the outer wheels need to cover a greater distance while the inner wheels travel a shorter distance within the same time. The differential handles this variation in wheel speeds using a sun and planet gear system. Further details of the differential will be discussed later.

Axle is the next component of transmission system. The axle receiving power from the engine is termed as ‘live’ axle. It is in two halves. The ends of the axle have road wheels connected to it. These road wheels are in direct contact with the road surface. The body of the automobile is above the axle. The axle also takes up the various loads including the weight of the automobile. It also transmits motion to the road wheels.

The Body

Most manufacturers have phased out the use of a separate frame for attaching the body structure, except in certain commercial heavy-duty vehicles. Instead, many heavy vehicles now use simple sub-frames to support the engine and gearbox. These sub-frames mount directly onto the main frame using rubber mounts that help isolate engine vibrations.

Advancements in spot welding and sheet pressing techniques have led most manufacturers to adopt integral construction in vehicles. In this design, the body itself serves as the frame, and all assembly units attach directly to it. This approach makes the vehicle more compact, reduces weight, and lowers manufacturing costs. Some intermediate designs also exist, where a light chassis combines with a pressed steel body. In these cases, manufacturers strengthen the chassis by using a steel sheet platform.

In addition to the four basic components, the automobile includes control systems and auxiliaries. The control systems manage the motion of the vehicle and play an essential role in its operation.These include

(b) Braking system or brakes.

Steering system

Braking system

The Auxiliaries

Lubrication System

An engine has many moving parts which eventually develop wear, as they move against each other.The engine circulates oil between these moving parts to prevent the metal-to-metal contact that results in wear. Oiled parts move more easily with less friction, which minimizes power loss due to friction.The secondary function of a lubricant is to act as a coolant and also as a sealing medium to prevent leakages. Finally, a film of lubricant on the cylinder walls helps the rings in sealing and thus improves the engine’s compressions.

Cooling System

Fuel System

Ignition System

Fundamentally, the ignition system assists combustion by delivering a high-voltage spark—or enabling self-ignition—in each engine cylinder at the precise moment. Consequently, this ensures complete burning of the air-fuel mixture.

To begin with, the engine must ignite the fuel supplied to the combustion chamber to deliver power. In the case of a spark-ignition engine, it generates an electric spark to ignite the fuel. On the other hand, a compression-ignition engine achieves ignition by compressing the mixture to a high pressure. As a result, it eliminates the need for a separate ignition system.

Electrical System

Suspension System

- Rigid system

- Independent system

In the rigid system, the road springs connect directly to a rigid beam axle. Manufacturers mostly use this system on the front axles of commercial vehicles and the rear axles of all types of vehicles.

Power Train

Clutch

Drive Shaft

Differential

Axles

Wheels

Steering System

Braking System

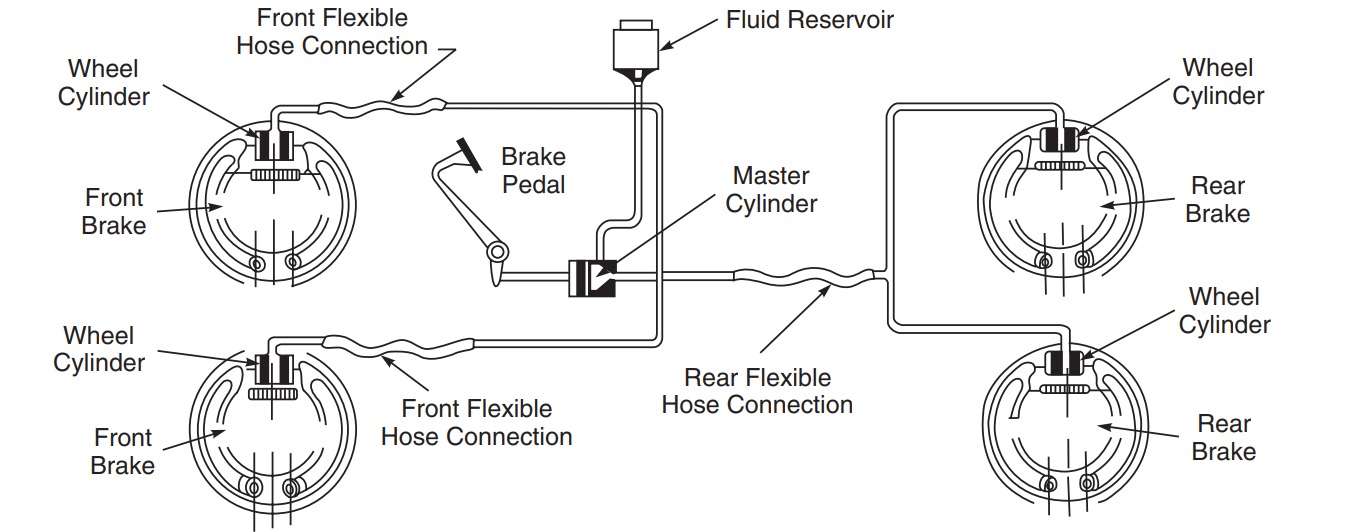

Drivers consistently use brakes to slow down or stop a moving vehicle. Moreover, the braking system plays a crucial role in ensuring the safety of both passengers and pedestrians on roads. Additionally, manufacturers design braking systems to function either mechanically or hydraulically. In fact, hydraulic systems currently make up approximately 95% of all braking systems in operation.

All brakes consist of two members, one rotating and the other stationary.Various mechanisms bring the two members into contact to reduce the vehicle's speed.Figure 9 shows the simplified layout of a hydraulic braking system.

The major components of the braking system are: brake pedal, master cylinder, wheel cylinders,brake drum, brake pipe, brake shoes, brake packing plant and linkages. As vehicle load and speed have increased in recent times, modern drivers place greater importance on brake systems and increasingly prefer power brakes.Power brakes utilize vacuum and air pressure to provide most of the brake-applying effort.