Introduction

Iron is one of the most important and versatile elements, shaping human history from ancient times to modern industry. This blog explores its properties, uses, and lasting impact on our lives.

Chemical and Physical Properties

- Density and Melting Point: In other words, iron can be identified as a relatively heavy metal with a density close to 7.87 g / cm3. It holds a relatively high melting point- (1,538 degrees Celsius) which make it ready for high-temperature applications.

- Magnetic Properties: Introducing a field, the iron is ferromagnetic i.e it is characterized by the strong magnetic outcome. These unique features enable iron to be used for the creation of transformers, motors, electrical industries, and other magnet-based technologies.

- Corrosion Resistance: While pure iron is bad at being rust proof when the part of it is there is moisture and oxygen, there is the group of iron alloy, called stainless steel, which has the properties of high corrosion resistance because chromium and the others are added as the alloy elements.

- Ductility and Malleability: As it often the case, iron exhibits ductility and mallability, i.e. it can be pulled into wires and bounded into thin plates without braking them. This characteristic of the range of iron alloys endows them with such an incredible adaptability and malleability that they are especially fit for the performance of different manufacturing procedures.

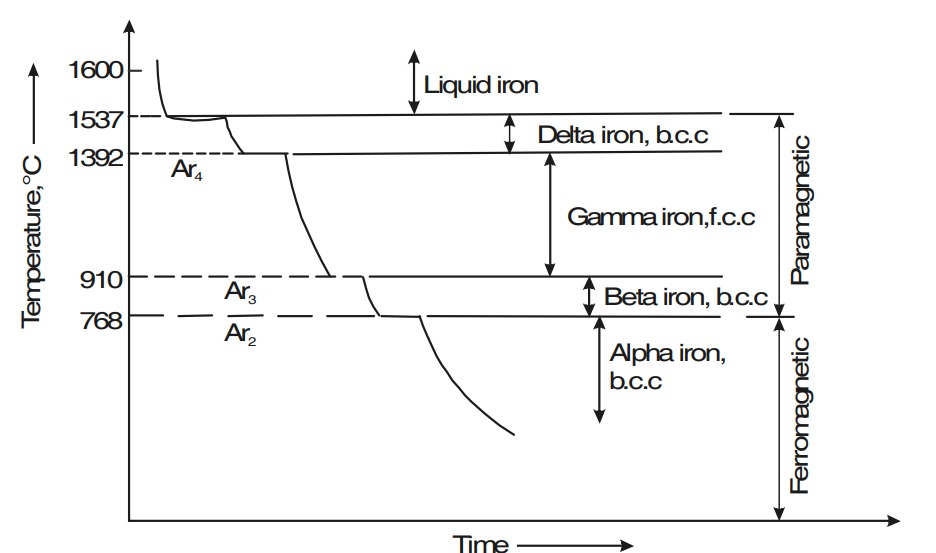

Cooling curve for pure iron

Iron may exist in several allotropic forms in the solid state at different temperatures.The transformation of iron from one allotropic form to another is accompanied either by the evolution of heat or absorption of heat. Fig. 1 shows the cooling curve of pure molten iron (melting point ⋍ 1537 ° C) plotted in time v’s temperature coordinates.

The first horizontal step appears on this curve at a temperature of 1537° C. It indicates that heat is evolved and that iron passes from the liquid to solid state. The mixture consists of liquid plus delta (δ)- iron solid solution. Delta iron has body centred cubic (b.c.c.) crystal lattice. The second temperature effect occurs at 1392° C and delta iron gets transformed into gamma (γ)- iron, which has a face centered cubic (f.c.c.) lattice.

Next step is at 910° C where γ -iron is transformed into beta (β)- iron with b.c.c. lattice. The fourth step is observed at 768° C, where β - iron is transformed into alpha (α) -iron with (b.c.c.) lattice. α - iron acquires pronounced ferro-magnetic properties.

There are actually two allotropic forms of iron : α - iron and γ - iron as follows : –

- δ - iron (b.c.c.) : 1392° C – 1537° C

- γ - iron (f.c.c.) : 910° C – 1392° C

- β - iron (b.c.c.) : 768° C – 910° C

- α - iron (b.c.c.) : < 768° C

β-iron may be regarded as a paramagnetic state of α - iron.

Critical Points. On the cooling curve (or on the heating curve), the points where structural changes occur, are known as “critical points”. In Fig 1, the critical point of the α⇌γ.

transformation at 910° C is denoted by Ar3 (in cooling) and by Ac3 (in heating). The critical point of the γ⇌α transformation at 1392° C is denoted by Ar4 (in cooling) and by Ac4 (in heating). Again, the critical point (768° C) corresponding to magnetic transformation of α = iron is denoted by Ar2.Letter A denotes arrest, r for cooling and c for heating. The significance of “arrest” lies in the fact that structural changes take place at constant temperature.

Absolutely pure iron is very difficult to obtain. But, in this state, it is a soft and very plastic material of not much use in engineering.

However, it can be alloyed with many elements. Alloys of iron and carbon are the most widely used in engineering.

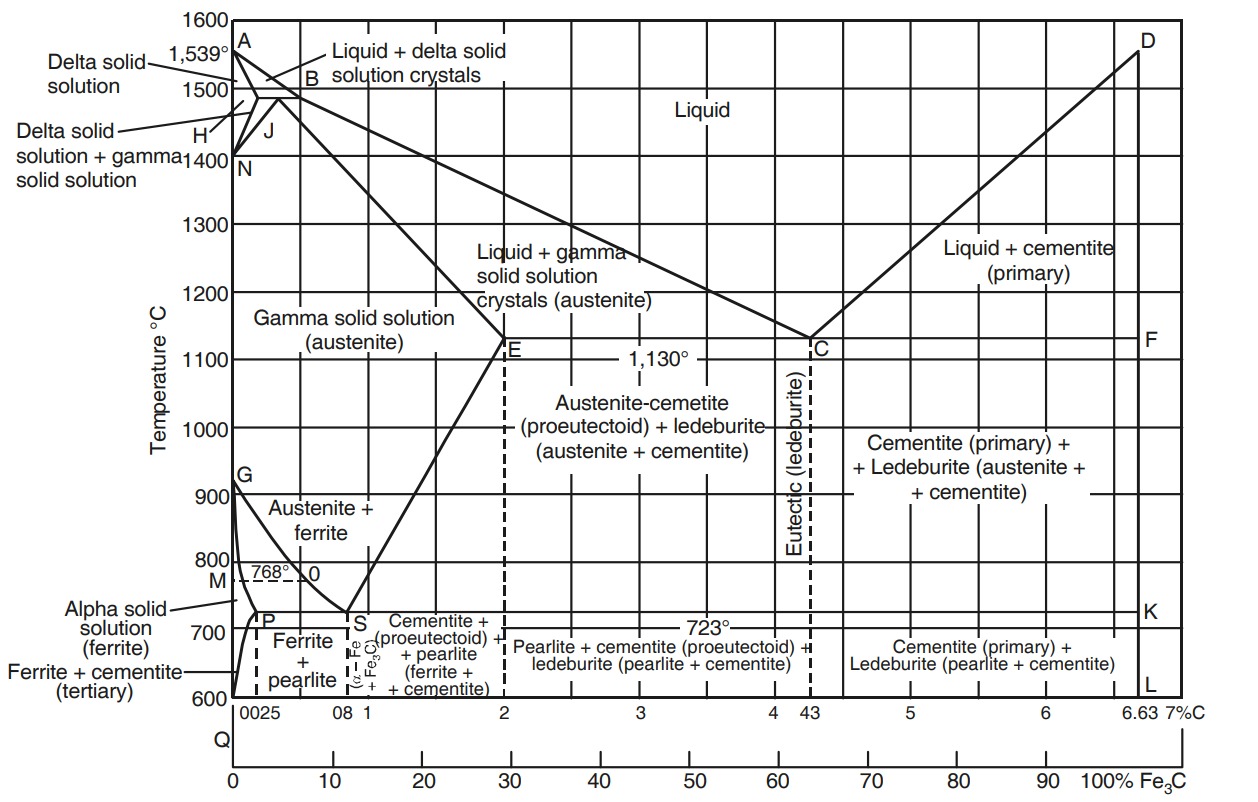

The iron-carbon equilibrium diagram

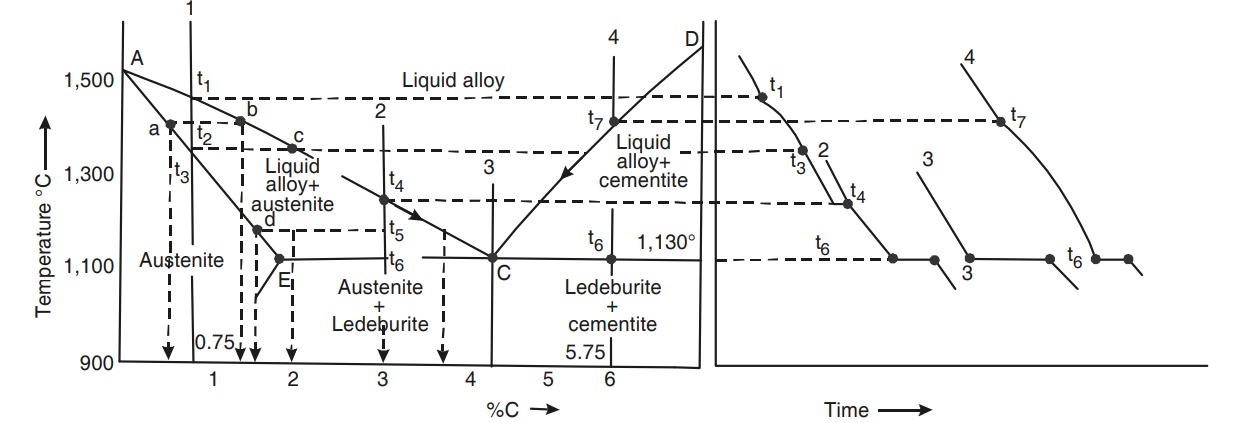

A modern version of the iron-carbon equilibrium diagram is illustrated in Fig. 2.

The iron-carbon equilibrium diagram concerns transformations that occur in alloys having compositions from pure iron to cementite (6.67 per cent C). Point A (1539°C) on the diagram is the melting point of pure iron and point D (∼1550° C) is the melting point of iron carbide (cementite, Fe3C). Points N (1,401°C) and G (910° C) correspond to the allotropic transformations at α - iron into γ- iron. Point E shows the solubility limit of carbon in γ- iron at 1,130°C (2.0 percent).

The upper left-hand portion of the diagram represents the allotropic transformations γ⇌α (δ) at high temperatures. At temperatures on the line AB, crystals of the solid solution of carbon in α - iron ( δ solution) begin to precipitate from the liquid alloy. The line HJB represents peritectic transformation taking place at a constant temperature. The result of the peritectic reaction is the formation of the solid solution of carbon in γ - iron, i.e., austenite.

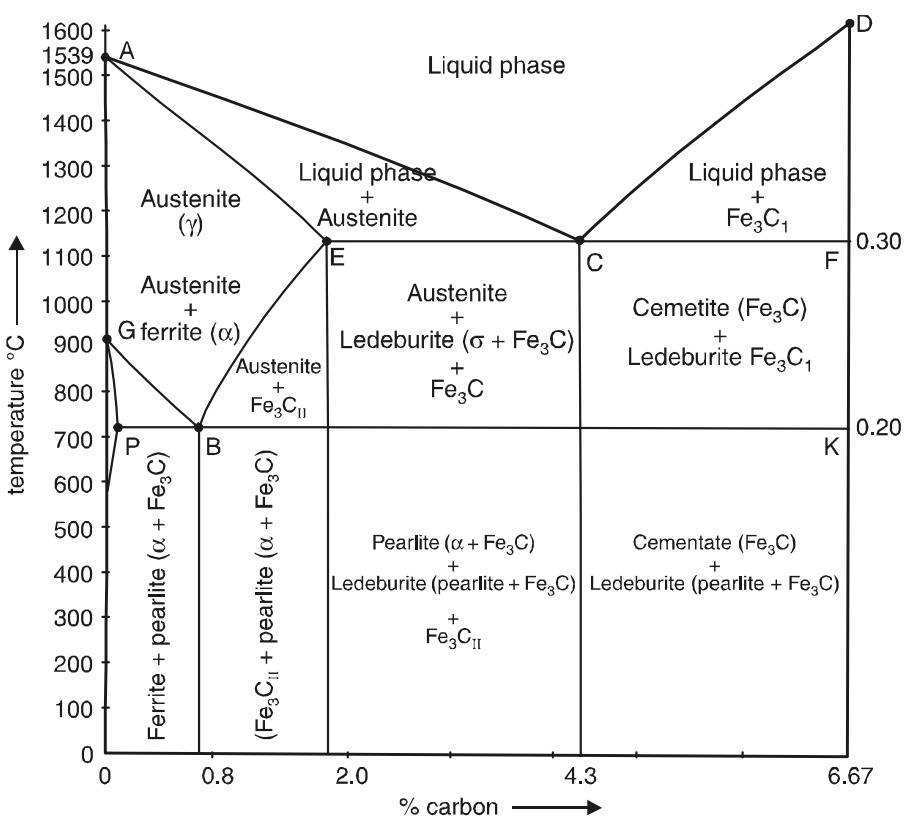

To simplify further study of the iron-carbon diagram we shall ignore this part of the diagram in the future since it is no practical importance. A simplified iron-carbon diagram is shown in Fig 3.

The alloys begin to solidify when they reach a temperature on the ACD (liquidus) line (Fig. 3). They complete solidification at the solidus temperatures along line AECF. Along line AC, the liquid alloy precipitates austenite, while along line CD, it precipitates cementite. At point C—where the temperature is 1,130°C and the carbon content is 4.3%—the liquid alloy simultaneously precipitates austenite and cementite, forming a eutectic called ledeburite. All alloys with more than 2.0% carbon (cast irons) that solidify completely at 1,130°C (line ECF) form the eutectic ledeburite.

A discussion of the primary solidification (transformation from the liquid to the solid state) of steels containing 0.75 per cent C and cast irons containing 3, 4.3, and 5.75 per cent C will clarify the interpretation of the diagram.

- Here the solid solution of carbon in γ - iron, austenite, begins to precipitate from the liquid alloy. The amount of austenite continuously increases as the temperature falls and its composition varies along the solidus (AE) while that of liquid phase varies along the liquids (AC). For example, at a temperature t.

- Point a shows the composition of austenite, and point b indicates the composition of the liquid phase. This steel completely solidifies at temperature t.

- At the moment the solidification process completes, steel of any composition forms only austenite. Every steel composition follows the same solidification pattern. Cast iron containing 3.0 per cent carbon begins to solidify at temperature t.

- At any temperature t lying on the liquidus line (AC), the liquid alloy begins to precipitate austenite crystals, and their amount continuously increases as the temperature drops. You can determine the compositions of both the austenite and the remaining liquid phase at any given temperature t.

- By drawing a line through this temperature, parallel to the abscissa so that it intersects the liquids and the solidus, Point d indicates the austenite composition and point e, the composition of the liquid phase which is in equilibrium at temperature t.

- The lever rule determines the proportion of liquid and solid phases at any temperature between the liquidus and solidus. Thus, at temperature t, we can calculate these proportions directly.

- The ratio

t₅d / t₅eexpresses the quantitative proportion of these phases. Cast iron with 3.0 percent carbon completes its solidification at temperature t. - (1130° C). At this temperature, the liquid phase, enriched in carbon up to 4.3 percent (the eutectic concentration), is finally solidified. From it, saturated austenite crystals (2.0 per cent C) precipitate,simultaneously with cementite to form the eutectic mixture, ledeburite.Therefore, directly following solidification,the cast iron will consist of primary austenite crystals and ledeburite, formed at 1130° C)(t).

- All cast irons containing between 2.0 to 4.3 percent carbon (hypoeutectic cast irons) solidify in the same manner as described above.

An alloy containing 4.3 per cent C (eutectic cast iron) differs from the previous alloys in that it solidifies at a constant temperature (point C at 1,130°C). Above this temperature, the alloy will be in a liquid state and when the temperature falls to 1130° C (point C), the alloy solidifies at this constant temperature forming ledeburite.

Solidification of the eutectic alloy at a constant temperature conforms to the phase rule. In a two component system containing three phases (liquid phase, austenite, and cementite) F = 2 +1 – 3 = 0, i.e., the system is nonvariant. All three phases have definite compositions (liquid phase = 4.3 per cent C, austenite – 2.0 per cent C, and Fe3 C – 6.67 per cent C) and the transformation temperature is constant at 1,130° C. A horizontal step on the cooling curves (Fig. 4) corresponds to the formation of the eutectic ledeburite).

Cast iron with 4.3% C consists solely of ledeburite after solidification. Hypereutectic cast irons (4.3–6.67% C) begin solidifying along line CD by precipitating cementite (Fe₃C) from the liquid alloy, as shown in Fig. 4. For example, a cast iron with 5.75% C starts solidifying at temperature t₁₀, where cementite crystals form. As cementite, the carbon-rich phase, precipitates, it reduces the carbon content of the remaining liquid along the liquidus CD. At 1,130°C, the alloy reaches the eutectic composition (4.3% C) and solidifies at a constant temperature to form ledeburite. The fully solidified alloy contains primary cementite and ledeburite. All hypereutectic alloys solidify similarly.

Thus, all steels consist of austenite after the primary crystallization, while all cast irons consist of ledeburite and primary crystals of excess austenite (hypoeutectic cast irons containing from 2.0 to 4.3 per cent C) or cementite (hypereutectic cast irons containing from 4.3 to 6.67 per cent C).

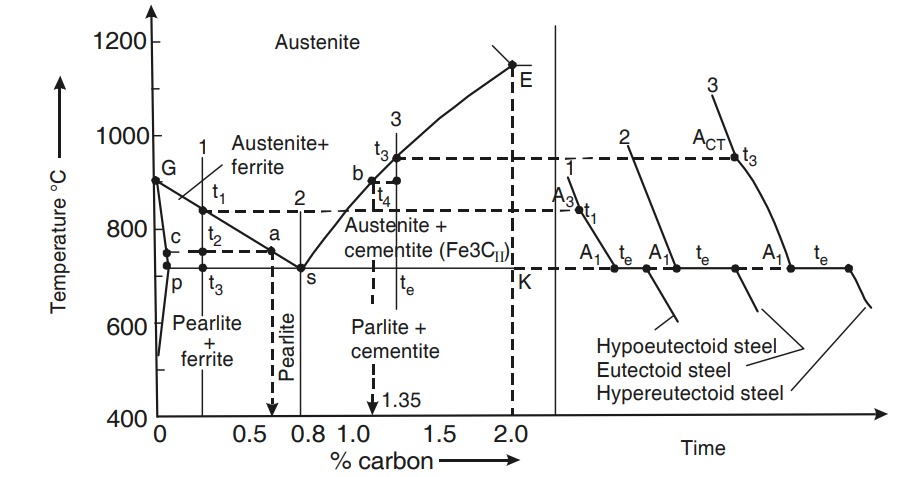

Let us now examine the secondary crystallisation transformations that occur in the solid state. In iron-carbon alloys, these transformations involve the conversion of γ-iron (austenite) to α-iron (ferrite) and the decomposition of austenite. The line GS in the equilibrium diagram (Figures 3 and 5) marks where austenite begins to decompose and ferrite starts to precipitate from it.

Metallurgists designate the critical points along the GS line as Ac3 during heating and Ar3 during cooling. The SE line marks the temperatures where austenite begins to decompose and precipitate excess carbon as cementite. Experts refer to this form as secondary or proeutectoid cementite, which distinguishes it from cementite that forms directly from the liquid phase. The Acm points define the specific temperatures along the SE line. Point S, which corresponds to 0.8% carbon, indicates the lowest temperature (723°C) at which austenite remains stable in equilibrium. At this point, austenite decomposes and simultaneously precipitates ferrite and cementite, forming the eutectoid mixture known as pearlite.

The formation of pearlite proceeds at a constant temperature since, in the presence of three phases of constant composition (austenite, ferrite, and cementite), the number of degrees of freedom of the system will be zero (F = 2 + 1 = 3 0). Consequently, there is a horizontal step on the cooling curve at the pearlite formation temperature (Fig. 5).

Pearlite forms a structure of thin, alternating plates of cementite and ferrite, known as lamellar pearlite. Metallurgists can produce a different structure—granular or divorced pearlite—by applying a specific heat treatment. This form features rounded globules of cementite dispersed within a ferrite matrix.

- All iron-carbon alloys decompose austenite to form pearlite along the PSK line at 723°C. Metallurgists designate the temperature at which pearlite forms during cooling as Ar₁. During heating, pearlite transforms back into austenite at a temperature known as Ac₁.

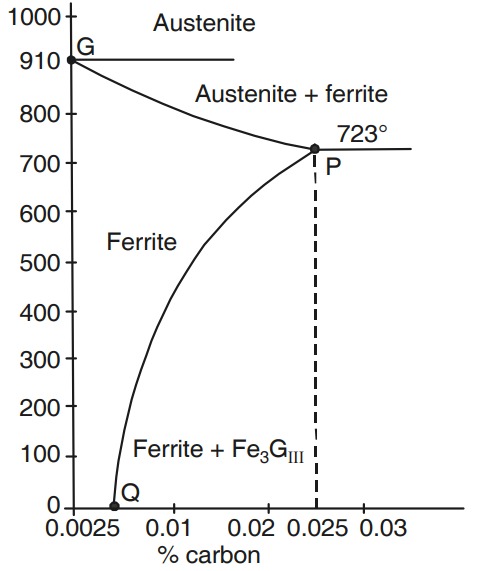

- Point P in Figs. 5 and 6 marks the maximum solubility of carbon in α-iron at 723°C (0.025 percent). Just as the line SE, starting from point E, shows how the solubility of carbon in γ-iron (austenite) decreases with temperature, the line PQ, starting from P, shows how the solubility of carbon in α-iron (ferrite) also decreases upon cooling. Alloys with carbon content between points P and Q contain ferrite and excess (tertiary) cementite, which usually precipitates along the boundaries of the ferrite grains (Fig. 6). The line PQ defines the composition of the ferrite. After complete cooling, alloys with carbon content to the left of point Q form only a solid solution of carbon in α-iron, consisting entirely of ferrite grains.

- Next, we will follow the transformations that occur in steels containing 0.025 to 0.8 percent carbon (hypoeutectoid steels) as they cool from the austenite region.

- The diagram (Fig. 6) shows that no changes occur in the alloy until the temperature drops to the line GS. In this range, the alloys have a single-phase, austenite structure. Ferrite precipitates from the austenite at temperatures below line GS. Thus, a two- phase state exists below line GS: austenite (γ) and ferrite (α).

- Since the ferrite precipitating from the austenite upon further cooling contains very little carbon, the carbon concentration of the remaining austenite will continuously increase along the line GS.

- For example, in cooling a 0.2 per cent C steel, the austenite at temperature t2 will have a carbon content corresponding to point ‘a’ (Fig 7) while that of the ferrite will correspond to point c.Upon further cooling the carbon content of the austenite will increase and at a temperature of 723° C (Ac1), it will reach 0.8 per cent.

- Austenite with eutectoid composition decomposes at a constant temperature of 723°C and forms pearlite.

- Thus, hypoeutectoid steels (which contain less than 0.8% carbon) form a structure of ferrite and pearlite when they cool completely. As the carbon content increases, these steels develop more pearlite and less ferrite in their microstructure.

- As steels with more than 0.8% carbon (hypereutectoid steels) cool, additional transformations take place. The line ES shows how the solubility of carbon in austenite decreases during cooling. Austenite exists alone above the ES line. When the temperature reaches the ES line, the austenite becomes saturated with carbon. As the temperature continues to drop, the excess carbon precipitates as cementite. Consequently, below the ES line, the microstructure includes two phases: austenite and secondary (or proeutectoid) cementite (Fe₃CII), as shown in Fig. 7.

- As cementite precipitates along the line ES, the austenite loses carbon. At temperature t₄, the austenite in a hypereutectoid steel with 1.35% carbon retains only 1.2% carbon (at point b) during cooling.

- At the temperature 723° C (Ac1) the austenite will contain 0.8 per cent C and will decompose at this constant temperature into the ferrite-cementite eutectoid mixture which we call pearlite.

- Thus, completely cooled hypereutectoid steels (0.8 to 2.0 per cent C) will have a structure consisting of pearlite and excess (proeutectoid) cementite.

We can now examine the transformations that occur in cast irons. As previously mentioned, cast irons form ledeburite after primary crystallization. This eutectic consists of saturated austenite (2.0% carbon) and cementite. In hypoeutectic cast irons (2.0% to 4.3% carbon), the structure includes ledeburite and primary austenite crystals, which contain 2.0% carbon. In contrast, hypereutectic cast irons (4.3% to 6.67% carbon) form primary cementite in addition to ledeburite.

As cooling continues, carbon solubility in austenite decreases along line SE, and primary austenite crystals begin to partially decompose. Simultaneously, eutectic austenite also decomposes, with both processes precipitating secondary cementite as line crystals.

Austenite composition changes along line SE. At line PSK (723°C), it reduces its carbon to the eutectoid level (0.8% C) and decomposes into ferrite and cementite, forming the eutectoid structure known as pearlite.

Therefore, when hypoeutectic cast irons cool completely, they form a structure consisting of pearlite, ledeburite (pearlite + cementite), and secondary cementite.

Eutectic cast iron consists of the eutectic – ledeburite-only. The ledeburite, in turn, consists of pearlite and cementite.

Hypereutectic cast irons contain ledeburite and precipitate primary cementite in the form of long plates or needles.

Uses and Applications

- Construction and Infrastructure: Iron and its alloys, especially steel, are fundamental materials in the building and infrastructure sectors. Materials such as steel, aluminum, copper, and other alloys are in demand for constructing bridges, buildings, highways, railways, and more due to their strength, durability, and ease of use.

- Transportation: Iron plays a vital role in enabling various modes of transport—road, sea, land, and air—to function effectively. Car manufacturers use iron to produce engine components, chassis, and wheels, resulting in vehicles that are both reliable and efficient.

- Machinery and Equipment: Modern manufacturing processes often use iron alloys to produce various household and industrial devices, including tools and machines. Industries rely on iron-based materials for their mechanical strength, wear resistance, and machinability, which enhance efficiency and performance.

- Energy Generation and Transmission: Coal supports the production of electrical generators, transformers, and power transmission infrastructure made of iron. It plays a key role in building transformers and supports the operation of systems that generate, transmit, and distribute electrical energy using metal components.

- Consumer Goods: Steel and its alloys make up countless consumer products such as furniture, cutlery, cookware, and appliances. People use these items daily in homes, offices, and commercial spaces. Their aesthetic appeal, durability, and affordability make them the top choice for such applications.