Introduction

Cast press is a fabric with a rich heritage and versatile applications. Traditionally used for pattern cutting, it has long served as a foundational material in design and construction. Beyond its flexibility, quality, and unique characteristics, cast press has emerged as a key material across various industries—from manufacturing to culinary arts. In this article, we delve into the world of cast press to explore its composition, classifications, properties, and, most importantly, the reasons behind its enduring appeal.

Understanding Cast Iron

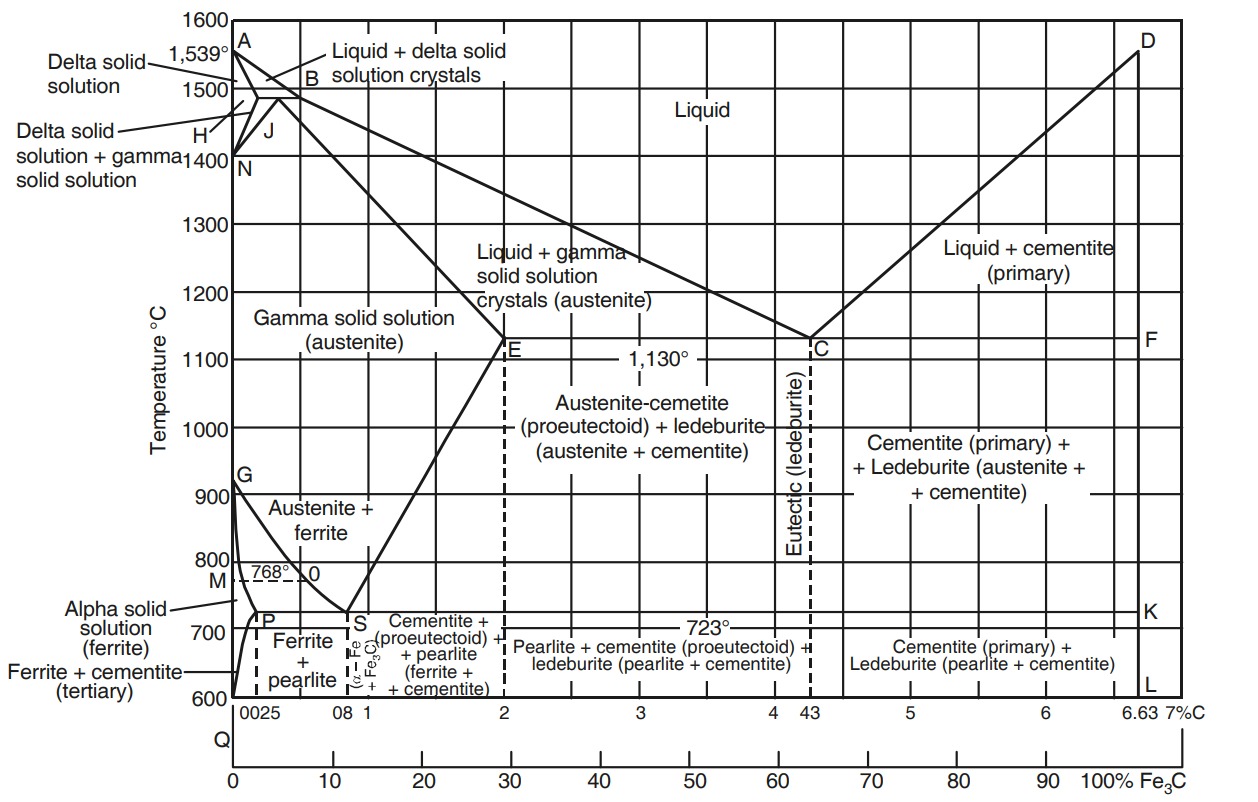

Cast iron is an alloy of iron and carbon. The region of cast iron in the iron-carbon equilibrium diagram is shown in Fig 1. The diagram shows that there is a eutectic at 4.3 % (point C) which has solidification temperature 1130° C. Metallurgists, for example, refer to alloys containing 2% to 4.3% carbon as hypo-eutectic irons because, in general, their carbon content falls below the eutectic composition. Therefore, these alloys, in this case, belong to the hypo-eutectic category. On the other hand, they classify alloys with carbon content between 4.3% and 6.67% as hyper-eutectic irons. This is because, comparatively, their carbon content, in fact, exceeds the eutectic composition. Moreover, as a result, such alloys fall into the hyper-eutectic range. In conclusion, despite the narrow range, this classification remains important. Consequently, metallurgists consistently apply it during alloy analysis.

Figure 1

With such a high carbon content, cast iron is very brittle and has low ductility. The general properties of cast iron are:

- Cheap material

- Good casting properties, e.g. high fluidity, low shrinkage, sound casting,etc.

- High compressive strength.

- Good machinability

- High abrasion resistance

- Good damping characteristic.

- High corrosion resistance

Composition of Cast Iron

Cast iron contains different elements in addition to iron. The composition of cast iron is given below :

- Carbon = 2 – 6.67 %

- Silicon = 0.5 – 1.0 %

- Sulphur = 0.06 – 0.12 %

- Phosphorus = 0.10 – 0.30 %

- Manganese = 0.10 – 1.0 %

- Allaying elements : Ni, Cr, Mo, Mg, Cu, V.

Classification of cast Iron

The primary types of cast iron are described below.

1.Gray cast Iron

- When the molten cast iron cools, its final structure depends on the form in which the carbon solidifies. This form, in turn, is influenced by the cooling rate and the composition of the material. Metallurgists control the structure primarily by adjusting the total carbon and silicon content (along with phosphorus). They express the combined influence of these elements through the carbon equivalent (C.E.).

`C.E.(%)=C%=frac{SI%+P%}3`

- At high carbon equivalent and slow cooling rates, cementite becomes unstable and decomposes into austenite and graphite flakes, a process called graphitization. Elements like silicon promote this change. The graphite flakes give the fracture surface a gray color, leading to the name gray cast iron.

- Gray C.I. is the most widely used of all cast irons. In fact, it is common to speak of gray cast iron just as cast iron. It contains 2.50 to 3.75% C and upto 2.5% Si.

- Gray cast iron offers softness, easy machinability, and moderate brittleness. It provides several key advantages: low cost, low melting point, excellent fluidity, and good damping capacity. Its structure contains free graphite, which acts as a lubricant. This property allows large machine slides made from gray cast iron to operate with very smooth and free-moving action.

- Product Applications:Industries often choose gray cast iron where high strength and ductility are not critical, mainly due to its low cost. Typical uses include weights, frames, motor and gear housings, pump housings, sanitary ware, pipe fittings, and underground gas and water pipes.

- Gray cast iron is used for machine tool bases and supports due to its high compressive strength and damping. Its fluidity and wear resistance suit it for engine blocks, brake drums, gears, piston rings, and crankshafts. It is also used in appliances, manhole covers, cylinder heads, rolling mill parts, and general machinery.

2.White Cast Iron

- At low values of C.E. < 3 (C upto 2.5 % and Si < 1.5 %) and rapid cooling, the cementite will not have sufficient time to break into graphite and austenite. As a result, the total carbon will be exclusively in the combined form of Iron Carbide, Fe3 C (Cementite). It is a very hard and brittle metal with the entire cross-section having a white microstructure. Due to this, the metal is virtually unmachinable except by grinding and so has very limited applications.

- Product Applications. Engineers primarily use white cast iron in wear-resistant applications, such as grinding balls, liners for ore-crushing mills and cement mixers, extrusion dies, and certain components in agricultural machinery. They also widely use white cast iron as a base material when producing wrought iron and malleable iron castings.

3.Malleable Cast Iron

Malleable castings are first made from white cast iron and then malleabilized by two methods : “Black heart method” and “white heart method”.

- Black heart method. They anneal white iron castings for several days at 850–1000°C in airtight pots with inert materials like iron oxide or slag. Heat partially removes carbon and converts the rest into free, globular carbon. Slow cooling produces a strong, soft, and moderately ductile ferritic malleable iron, commonly made in the USA.

- White heart method. In this method (decarburisation), the castings are placed in pots packed with an oxidising material. The oxygen combines with carbon in the castings, reducing its amount to less than 1%. This method is used in Europe, and the material is pearlitic malleable iron.

- The difference between gray cast iron and malleable cast iron lies in the form of free carbon. In gray cast iron, free carbon takes the shape of flat or plate-like particles. In contrast, malleable cast iron contains graphite in the form of irregularly shaped spherical particles, which provide much greater strength than flakes.

- Malleable C.I. is stronger, tougher, ductile, impact resistant, and easily machinable due to graphite. Since carbon change occurs only up to about 10 mm, it is unsuitable for heavy castings. Its use is more limited than gray C.I. because it costs more to produce and its superior mechanical properties are often unnecessary.

- Malleable cast iron is commonly used for complex-shaped parts that require significant machining, such as components in automotive and agricultural equipment like housings, yokes, and wheel hubs. Other applications include hinges, spanners, mountings, cranks, levers, thin-walled machine parts, brake pedals, spring hangers, and similar components.

4.Ductile Cast Iron

- Ductile cast iron, also known as Nodular Cast Iron or Spheroidal Cast Iron, offers a higher grade than malleable cast iron because its carbon precipitates as spherical graphite nodules, which form more perfect spheres than those in malleable cast iron. To produce ductile cast iron, metallurgists first completely desulphurise the molten metal. Then, they add small amounts of special alloys containing magnesium or cerium into the molten iron in the ladle. These additives cause the iron, during solidification, to form graphite as small spherical nodules.

- Ductile cast iron possesses high fluidity which permits the casting of intricate shapes with excellent combination of strength and ductility, Ductile cast iron can be produced in thicker pieces than those produced by malleable cast iron.

- Ductile cast iron is stronger, more ductile, tougher and less porous than gray cast iron. So, it is used in parts where density and pressure tightness is a highly desirable quality. These parts include : hydraulic cylinders, valves, pipes and pipe fittings, cylinder heads for compressors and diesel engines. Ductile cast iron is also used to make rolls for rolling mills, many centrifugally cast parts, pulleys, forming dies, pump housings and, in general, for parts subjected to impact loading or requiring a high elastic modulus.

5.Chilled Cast Iron

- Engineers refer to quick cooling as chilling and call the resulting product chilled iron. They create it by placing metal chills inside the mould near its surface. When they pour molten metal into the mould, it cools rapidly and forms a hard, wear-resistant surface (about 1 to 2 mm thick) made of white cast iron. Beneath this surface, the material remains as gray cast iron. Workers can machine chilled cast iron only by grinding. Industries use it to make stamping dies, mill and crushing rolls, railway wheels, car wheels, cam followers, and similar components.

6.Alloy Cast Iron

- Engineers intentionally add alloying elements to cast irons to overcome certain inherent deficiencies in ordinary cast irons and to achieve specific qualities for special applications. By controlling the rate of graphitization, they use these elements to develop special capabilities such as enhanced mechanical properties, greater resistance to heat, corrosion, wear, and brittle fracture. Alloying also improves both the castability and machinability of cast iron. Commonly used alloying elements include nickel, copper, chromium, molybdenum, vanadium, and boron.

7.Meehanite Cast Iron

- Mechanite cast iron, produced under patent protection, is made with the addition of a calcium - silicon alloy. Calcium silicide acts as a graphitizer and produces a fine graphite structure giving a casting of excellent mechanical properties. The basic gray cast iron used to obtain Mechanite iron is low in silicon and moderately low in carbon (about 2.5 to 3 %). Various grades of Mechanite are produced to meet special requirements.

- All Mechanite irons have high strength, toughness, ductility and easy machinability. These irons also respond to heat treatment. Mechanite cast iron is ideally suited for machine tool castings.

8.Mottled cast iron

- It is a mixture of gray and white cast irons, with white iron at the surface and gray iron at the core. Heating cast iron to red heat with powdered red hematite in an oven produces it, resulting in improved toughness.

Below table gives the chemical composition of main types of cast irons (excluding alloy cast irons).

| Metal | C | Si | Mn | S | P |

|---|---|---|---|---|---|

| row1 col 1 | 3.00 – 4.00 | 0.50 – 3.00 | 0.10 – 1.00 | 0.02 – 0.10 | 0.03 – 2.00 |

| row2 col 1 | 2.50 – 3.75 | 1.00 – 2.50 | 0.40 – 1.00 | 0.06 – 0.12 | 0.10 – 1.00 |

| Malleable cast iron | 2.20 – 3.60 | 0.40 – 1.10 | 0.10 – 0.40 | 0.03 – 0.30 | 0.10 – 0.20 |

| White Cast iron | 1.75 – 2.30 | 0.85 – 1.20 | 0.10 – 0.40 | 0.12 – 0.35 | 0.05 – 0.20 |

The mechanical properties and applications of cast iron are give in the below table.

| - | Cast iron | Composition wt. % | Condition | Structure | U.T.S. MPa | Y.S. MPa | Elong % | Typical Application |

|---|---|---|---|---|---|---|---|---|

| Gray cast iron | Ferritic | 3.4 C, 2.2 Si, 0.7 Mn | Annealed | Ferrite matrix | 180 | - | - | Cylinder blocks and head clutch plates |

| Pearlitic | 3.2 C, 2.0 Si, 0.7 Mn | As-cast | Pearlite matrix | 250 | - | - | Truck and tractor cylinder blocks, gear box | |

| Pearlitic | 3.3 C, 2.2 Si, 0.7 Mn | As-cast | Pearlitic matrix | 290 | - | - | Diesel engine castings | |

| Malleable cast iron | Ferritic | 2.2 C, 1.2 Si, 0.75 Mn | Annealed | Temper carbon and ferrite | 345 | 224 | 10 | General Engineering Service Machinability |

| Pearlitic | 2.4 C, 1.4 Si, 0.75 Mn | Annealed | Temper carbon and pearlite | 440 | 310 | 8 | General service with dimensional tolerance | |

| Martensitic | 2.4 C, 1.4 Si, 0.75 Mn | Quenched and tempered | Tempered martensite | 620 | 438 | 2 | High strength parts, connecting rods, yokes for universal joints | |

| Ductile cast iron | Ferritic | 3.5 C, 2.2 Si | Annealed | Ferrite | 415 | 275 | 10 | Pressure casting as valve and pump bodies |

| Pearlitic | 3.5 C, 2.2 Si | As-cast | Ferritic Pearlitic | 550 | 380 | 6 | Crank shafts, gears and rollers | |

| Martensitic | 3.5 C, 2.2 Si | Quenched and tempered | Martensitic | 830 | 620 | 2 | Pinions, gears, rollers and slides. |

Wrought Iron

- The word “Wrought” means that the metal possesses sufficient ductility to permit hot and,or cold plastic deformation.

- Wrought iron consists of nearly pure iron with 1–3% slag and trace elements. Manufacturers first remove all impurities to obtain pure iron. They then add molten slag from the open hearth and mix it thoroughly.

- Initially, the press removes excess slag. Then, a rolling mill forms billets. Consequently, the billets contain iron fibers with slag layers. In fact, these layers resist corrosion. Moreover, workers reheat billets into products. For example, they make bars and plates. In addition, manufacturers produce crane hooks and rivets. Furthermore, they form chains and couplings. As a result, the material is versatile. On the other hand, poor reheating affects quality. Therefore, temperature control is essential. In other words, accuracy ensures strength. Thus, proper handling improves performance. In conclusion, wrought iron remains valuable.

- Wrought iron exhibits ductility and softness, making it easy to forge and forge weld. It withstands sudden loads effectively. Unlike steel, it cannot be hardened or tempered. Alloying with nickel increases strength, and cold working followed by aging further improves it.

- A typical chemical composition of wrought iron is as given below:-

- C : 0.02 – 0.08 %, Si : 0.01 – 0.20 %, Mn : 0.02 – 0.10 %

- S : 0.02 – 0.04 %, P : 0.05 – 0.20 %

Effect of Impurities on Iron

The effects of impurities on iron are discussed below:

1. Sulphur

- Metallurgists generally consider sulphur harmful in cast iron. In gray cast iron, it counteracts the graphitizing effect of silicon, reduces fluidity during pouring, decreases strength, and increases brittleness. Therefore, engineers aim to keep its content as low as possible, preferably below 0.1%.

2. Manganese

- It encourages the formation of carbide and so, tends to whiten and harden cast iron. But it helps to control the harmful effects of sulphur. It has greater affinity for sulphur than for iron and it combines with sulphur to produce manganese sulphide, which is not objectionable. It is often kept below 0.75%.

3. Phosphorus

- Engineers add phosphorus to gray cast iron to improve its flowability, making it particularly useful for casting intricate designs and producing light engineering components where low cost is a priority. However, since phosphorus induces brittleness in cast iron, metallurgists typically limit its content to below 1.0%.

4. Silicon

- It is the important graphitizer for cast irons, which makes the cast irons soft and easily machinable. It also produces sound castings free from blow holes because of its affinity for oxygen. It is present in cast irons upto 2.5 %.

Effect of Alloying Elements on Cast Iron

1. Nickel

- Metallurgists add nickel to cast iron to refine its grain structure, enhance strength and toughness, and improve corrosion resistance. While nickel does not affect ductility, it acts as a graphitizer—though only half as effectively as silicon—thereby improving the machinability of cast irons. In low-alloy cast irons, nickel content typically ranges from 0.25% to 5.0%. Engineers use these alloys in steam and hydraulic machinery, compressors, and internal combustion engine components. In heat- and corrosion-resistant cast irons, manufacturers may use up to 35% nickel.

2. Chromium

- Metallurgists add chromium to cast iron to refine grain structure and enhance strength, hardness, and corrosion resistance. Chromium also improves the wear and heat resistance of cast iron. Gray cast irons designed for severe wear conditions often contain up to 8% chromium. Engineers use this alloy in various types of pumps. For components requiring higher resistance, the chromium content may range from 10% to 30%. However, chromium tends to inhibit graphitization.

3. Copper

- Metallurgists add copper to cast iron in amounts up to about 1.0%. It increases fluidity for better mold filling, enhances corrosion resistance, and improves mechanical properties—particularly toughness and hardness. Copper also slightly improves the machinability of cast iron by promoting the formation of graphite.

4. Molybdenum

- The presence of molybdenum in cast iron produces fine and highly dispersed particles of graphite and good uniform structure. This increases the strength and toughness and improves high temperature strength of cast iron. Its amount ranges from 0.25 to 1.25 %.Engineers frequently add molybdenum to cast iron in combination with nickel, chromium, or both.

5. Vanadium

- Metallurgists add vanadium to cast iron in amounts ranging from 0.10% to 0.50%. It refines the grain structure, increases strength, and improves resistance to fatigue stresses. However, it also reduces graphitization.

6. Boron

- Until quite recently, boron received little recognition as an addition to regular gray cast iron. 0.05% boron, 3.5 % carbon and 1.0 % silicon in cast iron help to increase surface hardness and refine structure. Engineers use this alloy for rolls in rolling mills.

Properties of Cast Iron

- High Strength: Cast iron provides high compressive strength, which suits load bearing structures in the construction as well as in the machinery.

- Excellent Wear Resistance: Metallurgists often choose specific types of cast iron, such as gray cast iron and white cast iron, for components exposed to abrasive wear because these materials resist wear exceptionally well.

- Good Machinability: Gray cast iron is almost unparalleled in machinability, making complex shapes and complex components quite easy to produce.

- Thermal Conductivity: Cast iron conducts heat exceptionally well, making it ideal for applications where efficient heat transfer is crucial—such as in engine blocks and cookware.

- Damping Capacity: Cast iron has an incredible damping capability. It absorbs vibrations and makes noise as a result of the use of equipment and machinery.

Conclusion

Cast iron exemplifies the inventiveness and versatility of metallurgy. It combines wear resistance, machinability, and strength. Manufacturers have used cast iron for everything—from shaping the engine blocks of early cars by hand to producing simple frying pans for everyday kitchens. Even today, cast iron forms the backbone of countless applications across the world. When we group metals and analyze their properties, we gain valuable insight into their durability and widespread use across various industries.