Introduction

Plain concrete cement

- Binding material (like cement, lime, polymer)

- Fine aggregate (sand)

- Coarse aggregates (crushed stone, jelly)

- Water

In addition to selecting appropriate materials, engineers may also add a small quantity of admixtures—such as air-entraining agents, waterproofing agents, and workability agents—to the plain concrete mixture in order to impart special properties. These admixtures, though used in limited amounts, can significantly enhance the performance of concrete under specific conditions. For example, air-entraining agents improve freeze-thaw resistance, while waterproofing agents reduce permeability. Consequently, the use of admixtures allows engineers to tailor concrete mixes to meet the demands of various environmental and structural requirements.

1:1:2, 1:1½:3, 1:2:4, 1:3:6, and 1:4:8, representing the weights of cement, sand, and coarse aggregate, respectively. While proportioning concrete, they ensure that the sand fills the voids in the coarse aggregates and the cement paste fills the voids in the sand. Engineers commonly adopt the following proportions for various types of work, as shown in the table below.| S. No. | Proportion | Nature of Work |

|---|---|---|

| 1 | 1:1:2 | For machine foundation, footings for steel columns and concreting under water. |

| 2 | `1:1_2^1:3` | Water tanks, shells and folded plates, for other water retaining structures. |

| 3 | 1:2:4 | Commonly used for reinforced concrete works like beams, slabs, tunnel lining, bridges |

| 4 | 1:3:6 | Piers, abutments, concrete walls, sill of windows, floors |

| 5 | 1:4:8 | Mass concretes like dam, foundation course for walls, for making concrete blocks |

Functions of Various Ingredients of concrete cement

- Cement acts as the binding material. After adding water, it undergoes hydration and binds the aggregates as well as surrounding surfaces like stone and bricks. Generally, using a richer mix—with more cement—results in greater strength. The setting process begins about 30 minutes after mixing and completes in approximately 6 hours. Therefore, workers should place the concrete into its mould within 30 minutes of mixing and must protect it from any external forces until it has fully set.

- Coarse aggregate consists of crushed stones. Engineers prefer well-graded stones of igneous origin that are clean, sharp, angular, and hard. These aggregates add mass to the concrete and help prevent cement shrinkage. Fine aggregate consists of river sand, which also helps reduce shrinkage. When cement surrounds the sand, it gains mobility, fills the voids in the coarse aggregate, and enables proper binding of all ingredients. Sand also increases the density of the concrete by filling these voids. As a result, denser concrete leads to greater strength.

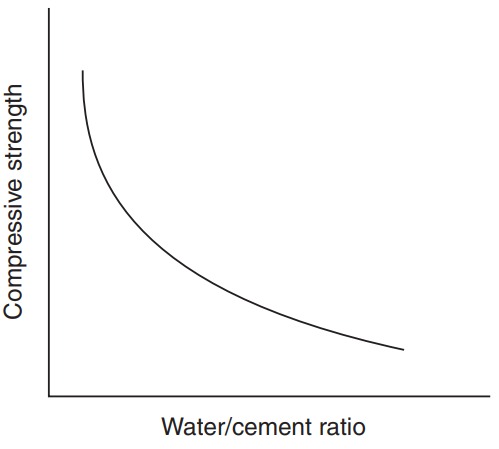

- Builders use clean water to make concrete. Water activates the hydration process in cement and transforms the mixture into a plastic mass. Once set, the concrete hardens into a solid structure. Water also provides workability to concrete, allowing workers to mix it easily and place it in the desired position. While adding more water improves workability, excessive water reduces the final strength of the concrete. Figure 1 illustrates how concrete strength varies with the water-cement ratio. To balance workability and strength, builders typically use a water-cement ratio of 0.4 to 0.45 for machine mixing and 0.5 to 0.6 for hand mixing.

Preparing and Placing of Concrete cement

- Batching

- Mixing

- Transporting and placing

- Compacting

1. Batching

- Volume batching

- Weight batching

- Volume Batching:

In this method, workers batch cement, sand, and coarse aggregate by volume. They use a gauge box made from wooden plates, with a volume equal to that of one bag of cement. One cement bag occupies a volume of 35 litres. Workers measure the required amounts of sand and coarse aggregate by filling the gauge box accordingly. After deciding the water-cement ratio, they calculate the quantity of water needed. For example, if the water-cement ratio is 0.5, then one bag of cement (50 kg) requires 0.5 × 50 = 25 kg of water, which equals 25 litres. Workers use suitable containers to measure and add the required water.

However, volume batching is not an ideal method. Wet sand occupies more volume than dry sand of the same weight, a phenomenon known as bulking of sand. This bulking disturbs the measured volumes and leads to inaccurate proportions in the concrete mix.

- Weight Batching:

Engineers recommend this method of batching. In the field, workers use a weighing platform to measure the correct proportions of sand and coarse aggregates. Large weigh batching plants use automatic weighing equipment to ensure accuracy and efficiency in the batching process.

2. Mixing

- Hand Mixing

- Machine Mixing

- Hand Mixing: Workers begin by weighing the required amount of coarse aggregate for a batch and spreading it on an impervious platform. Then, they spread the required amount of sand over the coarse aggregate. After that, they use shovels to mix the materials in dry condition by repeatedly overturning the mix. Next, they spread the required amount of cement over the dry mix and continue mixing with shovels until the blend reaches a uniform texture. Once they achieve this, they gradually add water while continuing to mix. Finally, after adding the full amount of water, they continue mixing until the concrete reaches a uniform color and consistency. This mixing process typically takes 6–8 minutes after adding water. Although this method does not produce the highest-quality mix, it is commonly used for small-scale construction projects.

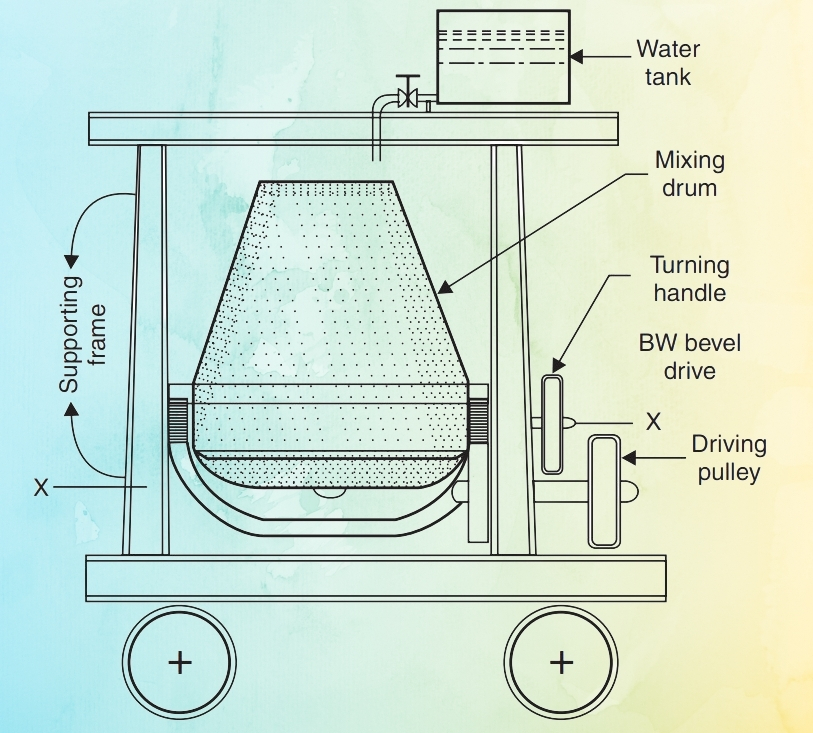

- Machine Mixing:For large and important projects, engineers prefer machine mixing. Figure 2 shows a typical concrete mixer. Workers place the required quantities of sand and coarse aggregates into the drum of the mixer. They rotate the drum 4 to 5 times to achieve dry mixing. Then, they add the required quantity of cement and continue dry mixing with another 4 to 5 drum rotations. After that, they gradually add water while rotating the drum for an additional 2 to 3 minutes, during which the drum completes about 50 rotations. By the end of this process, the mixer produces a uniform and homogeneous concrete mix.

3. Transporting and Placing of Concrete cement

After mixing, workers must transport the concrete to its final position. For small-scale works, they carry the concrete in iron pans, passing it hand to hand among a team of workers. They may also use wheelbarrows or hand carts for this purpose. In large-scale concreting, they transport concrete using chutes, belt conveyors, or pipes with pumps. During transportation, workers must ensure that segregation of the aggregate from the cement matrix does not occur.

Workers place concrete onto formwork. Before placement, they clean and properly oil the formwork to prevent sticking. If the concrete is to be placed for a foundation, they ensure the soil bed is well-compacted and free from loose soil.

Workers should place concrete as close as possible to its final position. If they drop it from a height, the coarse aggregates fall first, followed by the mortar matrix. This segregation weakens the concrete and should be avoided.

4. Compaction of Concrete cement

- Hand Compaction: In this method, workers compact the concrete manually by ramming, tamping, spading, or slicing it with tools. However, in intricate areas, they use a pointed steel rod—about 16 mm in diameter and one metre long—to poke and compact the concrete more thoroughly. This technique is simple yet effective for improving density in hard-to-reach sections. Therefore, proper manual compaction ensures better uniformity and durability.

- Compaction by Vibrators: Workers can compact concrete using high-frequency vibrators. Vibration reduces the friction between particles and sets them in motion, which helps release entrapped air and compacts the concrete effectively. Using vibrators also shortens the compaction time. When vibrators are used, workers can maintain a lower water-cement ratio, which further enhances the strength of the concrete. They should stop vibration as soon as cement paste appears on the surface. Over-vibrating the concrete can be harmful and should be avoided.

The following types of vibrators are commonly used in concreting:

Curing of Concrete cement

Curing may be defined as the process of maintaining satisfactory moisture and temperature conditions for freshly placed concrete for some specified time for proper hardening of concrete. Curing in the early ages of concrete is more important. Curing for 14 days is very important. Better to continue it for 7 to 14 days more. If curing is not done properly, the strength of concrete reduces. Cracks develop due shrinkage. The durability of concrete structure reduces.

- Spraying of water: Walls, columns, plastered surfaces are cured by sprinkling water.

- Wet covering the surface: Columns and other vertical surfaces may be cured by covering the surfaces with wet gunny bags or straw.

- Ponding: The horizontal surfaces like slab and floors are cured by stagnating the water to a height of 25 to 50 mm by providing temporary small hunds with mortar.

- Steam curing: In the manufacture of pre-fabricated concrete units steam is passed over the units kept in closed chambers. It accelerates curing process, resulting into the reduction of curing period.

- Application of curing compounds: Compounds like calcium chloride may be applied on the curing surface. The compound shows affinity to the moisture and retains it on the surface. It keeps the concrete surface wet for a long time.

Properties of Concrete cement

Properties of Green Concrete cement

1. Workability

This is defined as the ease with which concrete can be compacted fully without segregating and bleeding. It can also be defined as the amount of internal work required to fully compact the concrete to optimum density.The workability depends upon the quantity of water, grading, shape and the percentage of the aggregates present in the concrete.

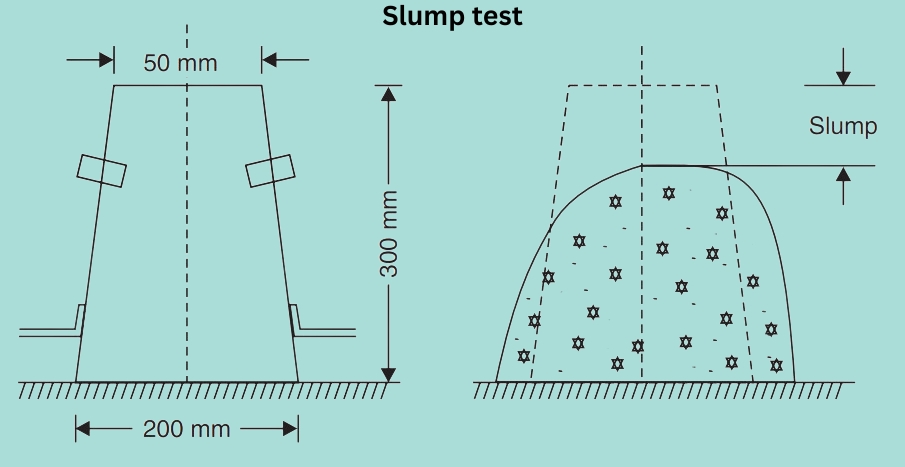

- The slump observed when the frustum of the standard cone filled with concrete is lifted and removed.

- The compaction factor determined after allowing the concrete to fall through the compaction testing machine.

- The time taken in seconds for the shape of the concrete to change from cone to cylinder when tested in Vee-Bee consistometer.

The suggested values of workability for different works are as shown in below Table.

| Application | Slump | Compaction Factor | Time in Vee-Bee |

|---|---|---|---|

| Concreting of shallow sections with vibrations | - | 0.75 – 0.80 | 10 – 20 |

| Concreting of light reinforced sections with vibrators | - | 0.80 – 0.85 | 5 – 10 |

| Concreting of lightly reinforced sections without vibrations and heavily reinforced sections with vibrations |

25 – 75 mm | 0.85 – 0.92 | 2 – 5 |

| Concreting of heavily reinforced sections without vibration | 75 – 125 mm | More than 0.92 | - |

2. Segregation

3. Bleeding

4. Harshness

Properties of Hardened Concrete cement

1. Strength

The characteristic strength of concrete is defined as the compressive strength of 150 mm size cubes after 28 days of curing below which not more than 5 percent of the test results are expected to fail. The unit of stress used is N/`mm^2`. IS 456 grades the concrete based on its characteristic strength as shown in the below Table.

| Grade | `M_{10}` | `M_{15}` | `M_{20}` | `M_{25}` | `M_{30}` | `M_{35}` | `M_{40}` |

|---|---|---|---|---|---|---|---|

| Characteristic strength in M N/`mm^2` | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

Till year 2000, `M_{15}` concrete was permitted to be used for reinforced concrete works. But IS 456–2000 specifies minimum grade of `M_{20}` to be used for reinforced concrete works.

Strength of concrete depends upon the amount of cement content, quality and grading of aggregates, water cement ratio, compaction and curing. Strength of concrete is gained in the initial stages. In 7 days the strength gained is as much as 60 to 65 per cent of 28 days strength. It is customary to assume the 28 days strength as the full strength of concrete. However concrete gains strength after 28 days also. The characteristic strength may be increased by the as factor given in the below Table.

| Minimum age of member when design load is expected. | 1 month | 3 month | 6 month | 12 month |

|---|---|---|---|---|

| Age factor | 1.0 | 1.10 | 1.15 | 1.20 |

formula `f_t=0.7sqrt{f_{ck}} `

N/`mm^2` where `f_{ck}` is the characteristic compressive

stress. The modulus of elasticity may be estimated from the formula;

2. Dimensional Change

Concrete shrinks with age. The total shrinkage depends upon the constituents of concrete, size of the member and the environmental conditions. Total shrinkage is approximately 0.0003 of original dimension.

Engineers define creep as the permanent dimensional change that concrete undergoes due to sustained loading over a long period. The amount of creep depends on the applied stress, the age of the concrete at the time of loading, and the duration of the load. To estimate the ultimate creep strain, use the values of the creep coefficient, which equals the ratio of ultimate creep strain to the elastic strain at the time of loading. The table below lists these values.

| Age of Loading | 7 days | 28 days | 1 year |

|---|---|---|---|

| Creep Coefficient | 2.2 | 1.6 | 1.1 |

The size of concrete may change due to thermal expansion also. The coefficient of thermal expansion depends upon the nature of cement, the type of aggregates, cement content, relative humidity and the size of the sections of the structural elements.Below Table shows the coefficient of thermal expansion of concrete with different types of aggregates.

| Type of Aggregate | Coefficient of Thermal Expansion/C° |

|---|---|

| Quartzite | (1.2 to 1.3) × `10^{-5}` |

| Sand stone | (0.9 to 1.2) × `10^{-5}` |

| Granite | (0.7 to 0.95) × `10^{-5}` |

| Basalt | (0.8 to 0.95) × `10^{-5}` |

3. Durability

4. Impermeability

Tests on Concrete cement

- Slump test

- Compaction factor test

- Crushing strength test

1. Slump Test

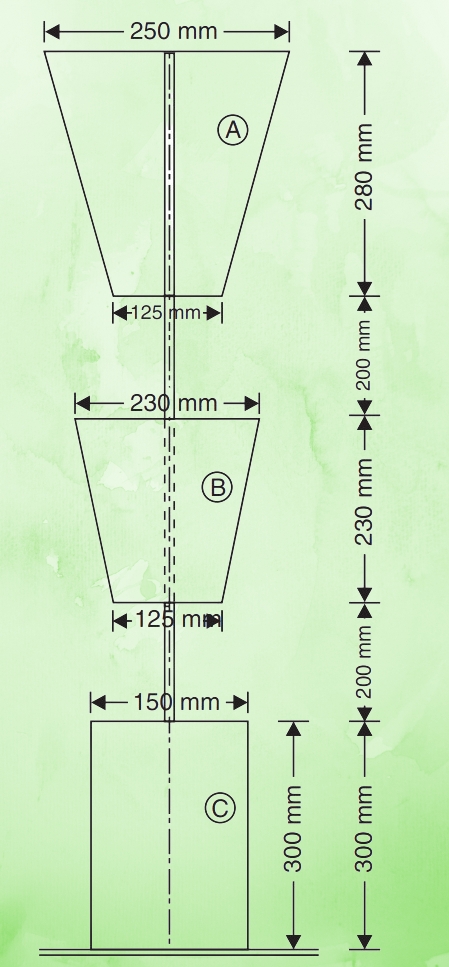

2. Compaction Factor Test

Engineers use this test to determine the workability of concrete in a laboratory setting. The equipment includes two hoppers and a cylinder mounted on a stand, with standardized dimensions and spacing between the three vessels. In a given setup, vessels A and B are equipped with hinged bottoms, allowing them to open or release contents when needed. In contrast, cylinder C has a fixed bottom, which prevents any such movement. This difference in design may affect how each vessel is used in practical applications, such as controlled discharge or containment.

Fill the top vessel A with the concrete sample. Immediately open its hinged door to let the concrete fall into vessel B. Next, open the hinged door of vessel B and allow the concrete to flow into cylinder C. Weigh the concrete collected in cylinder C and record the weight as W₁.

Fill the cylinder again with the same concrete sample in 50 mm layers. Compact each layer by ramming and vibrating. After compaction, weigh the concrete and record the weight as W₂.

Calculate the compaction factor by dividing `frac{W_1}{W_2}` .Refer to Table 2 for the specified compaction factor values for different types of construction work.

3. Crushing Strength Test

Technicians use metallic moulds of size 150 mm × 150 mm × 150 mm to cast concrete cubes. Before filling the mould, they properly oil its inner surfaces to ensure easy removal of the cubes. They fill the mould with fresh concrete in three layers and keep it in the room. After 24 hours, they remove the cube from the mould and place it under water for curing. After 28 days of curing, they test the cubes in a compression testing machine. During the test, they place each cube with the smooth surface (originally in contact with the side plates of the mould) facing downward. They record the crushing load and calculate the crushing strength by dividing the load by the surface area (150 × 150 mm²).

Code specify the desirable strength of concrete for 3 days and 7 days for quick assessment of strength of concrete.

Desirable Properties of Concrete cement

Hardened concrete cement should have

Uses of Concrete cement

- As bed concrete below column footings, wall footings, on wall at supports to beams

- As sill concrete

- Over the parapet walls as coping concrete

- For flagging the area around buildings

- For pavements

- For making building blocks

Engineers primarily use concrete as a key ingredient in reinforced and prestressed concrete. To begin with, builders construct many structural elements—such as footings, columns, beams, chajjas, lintels, and roofs—using reinforced cement concrete (R.C.C.). In addition, they use cement concrete to build various storage structures, including water tanks, bins, silos, and bunkers. Moreover, engineers rely heavily on concrete for large-scale infrastructure projects. For instance, they construct bridges, dams, and retaining walls as R.C.C. structures, with concrete serving as the primary construction material. As a result, concrete remains a fundamental material across a wide range of applications. This is mainly because of its strength, versatility, and durability. Consequently, the construction industry continues to depend on concrete for both storage and structural purposes, making it indispensable in modern building practices.

Conclusion

In conclusion, concrete stands as a testament to human ingenuity and innovation in the realm of construction. Its composition, properties, and versatility make it an indispensable building material, shaping the skylines of cities and the landscapes of communities around the globe. As we continue to push the boundaries of technology and sustainability, concrete remains a cornerstone of modern engineering, paving the way for a resilient and enduring built environment.