Introduction

SAND

- It contains salt and hence structure will remain damp. The mortar is affected by efflorenscence and blisters appear.

- It contains shells and other organic matter, which decompose after some time, reducing the life of the mortar.

- It sub-divides the paste of binding material into thin films and allows it to adhere and spread.

- It fills up the gap between the building blocks and spreads the binding material.

- It adds to the density of the mortar.

- It prevents the shrinkage of the cementing material.

- It allows carbon dioxide from the atmosphere to reach some depth and thereby improve setting power.

- The cost of cementing material per unit volume is reduced as this low cost material increases the volume of mortar.

- Silica of sand contributes to formation of silicates resulting into the hardened mass.

The properties of good sand are:

- It should be chemically inert.

- It should be free from organic or vegetable matter.

- It should be free from salt.

- It should contain sharp, angular and coarse grains.

- It should be well graded.

- It should be hard.

Understanding Mortar

Composition of Mortar

- Cement: Portland cement, most common type of the cement used in mortar performs the kneading function that makes the mixture hard.Cement gives wall units the necessary strength to stay together after construction.

- Sand: Grain is the additive agent in mortar which imparts mass and size to the medium of combination. The smoothness and the mixing proportion of the sand grains participate in the workability, strength,and texture differentiation of the mortar.

- Water: Water that is the medium in which cement hydrates and the sand mixes together to form plastic, workable paste. The right balance of water to cement is the most important factor for the of mortar.

Functions of Mortar

- Bonding: Mortar is the binding component that links masonry units together helping in maintaining the structural robustness and stability of the construction in the end.

- Load Distribution: Mortar perfectly shares out the load on the surface of the masonry units, preventing the formation of stress concentrations and breaks localized failure.

- Weatherproofing: Thayer is a bonding material too. It covers the gaps between the masonry units, protecting them from water penetration,cold draft, and so forth, against the outside agents.

- Aesthetic Enhancement: Mortar is not only the visual but also structural component of a masonry structure, with different mortar types, as well as finishes of mortar, offering a chance of different architectural styles and design effects.

Types of Mortar

CEMENT MORTAR

| S. No. | Works | Cement: Sand |

|---|---|---|

| 1 | Masonry works | 1:6 to 1:8 |

| 2 | Plastering masonry | 1:3 to 1:4 |

| 3 | Plastering concrete | 1:3 |

| 4 | Pointing | 1:2 to 1:3 |

- Curing: Cement gains the strength gradually with hydration. Hence it is necessary to see that mortar is wet till hydration has taken place.The process to ensure sufficient moisture for hydration after laying mortar/concrete is called curing. Curing is ensured by spraying water.Curing normally starts 6–24 hours after mortar is used. It may be noted that in the initial period water requirement is more for hydration and gradually it reduces. Curing is recommended for 28 days.

Properties of Cement Mortar

- When water is added to the dry mixture of cement and sand, hydration of cement starts and it binds sand particles and also the surrounding surfaces of masonry and concrete.

- A mix richer than 1:3 is prone to shrinkage.

- Well proportioned mortar provides impervious surface.

- Leaner mix is not capable of closing the voids in sand and hence the plastered surface is porous.

- The strength of mortar depends upon the proportion of cement and sand.Strengths obtained with various proportion of cement and sand is shown in below Table.

| S. No. | Cement: Sand | Compressive Strength |

|---|---|---|

| 1 | 1:3 | 10 N/`mm^2` |

| 2 | 1:4 | 7.5 N/`mm^2` |

| 3 | 1:5 | 5.0 N/`mm^2` |

| 4 | 1:6 | 3.0 N/`mm^2` |

| 5 | 1:8 | 0.7 N/`mm^2` |

Uses of Cement Mortar

- To bind masonry units like stone, bricks, cement blocks.

- To plaster slab and walls make them impervious.

- To give neat finishing to walls and concrete works.

- For pointing masonry joints.

- For preparing building blocks.

- As a filler material in ferro cement works.

- To fill joints and cracks in walls.

- As a filler material in stone masonry.

LIME MORTAR

Fat and hydraulic lime are used in lime mortar. Fat lime is mixed with 2–3 parts sand, while hydraulic lime uses a 2:1 sand ratio. Small batches are pounded; larger ones are ground.

- Pounding: For pounding pits are formed in hard grands. The size of pit is usually 1.80 m long,0.4 m wide and 0.5 m deep. It is provided with lining of bricks or stones. Lime and sand dry mixed with required proportion is placed in the pit. Small quantity of water is added at intervals. In each interval the mix is pounded with wooden pounders and mortar is turned up and down. The process is continued till uniform colour and desired consistancy is achieved.

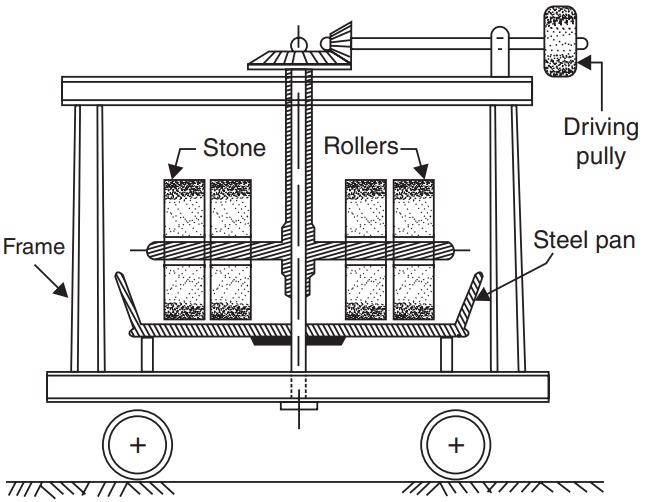

- Grinding: This is the better way of getting good mix. The grinding may be carried out in bullock driven grinding mill or in power driven grinding mill.

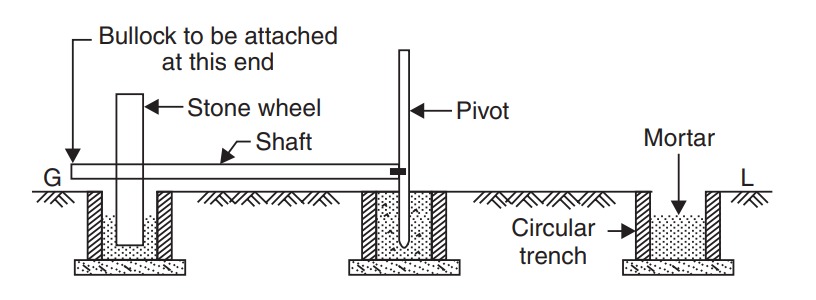

Figure 1 shows a bullock-driven mill with a circular trench, where a rotating stone wheel grinds mortar. Water is added gradually, and a worker turns the mix. It yields 1.7 m³ in 6 hours.

MUD MORTAR

Clay lumps are collected and are wetted with water and allowed to mature for 1 or 2 days. It is kneeded well until it attains required consistancy. Sometimes fibrous materials like gobber is added in the mix.It prevents cracks in the plaster. If plaster is to be used for outer walls, it is sprayed or painted with bitumen.

It is cheap mortar. Its durability is less. It is normally used for the construction of temporary sheds and cheap houses in rural areas.

SPECIAL MORTAR

- Cement clay mortar

- Gauged mortar

- Decorative mortar

- Cement Clay Mortar: Quality of clay mortar can be improved by adding cement to the mix.Normal proportion of clay to cement is 1:1. It maintains the economy to some extent and there is sufficient improvements in the durability of mud-mortar.

- Gauged Mortar: It is the mortar obtained by adding cement to lime mortar. The usual proportion of cement, lime and sand are 1:1:6, 1:2:9 and 1:3:12. This mortar is to be used within half an hour after mixing cement. Obviously, it is cheaper than cement mortar and its quality is between that of cement mortar and lime mortar.

- Decorative Mortar: These mortars are obtained by using coloured cement.They are used to give pleasant appearance to outer walls.

TESTS ON MORTAR

- Crushing Test

- Tensile Strength Test

- Adhesive Test

- Crushing Test: This test is carried out on a brick work with the mortar. This brick work is crushed in a compression testing machine and the load is noted down. Then the crushing strength is obtained as load divided by cross-sectional area.

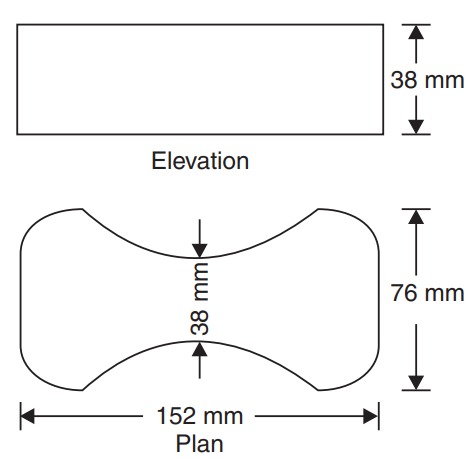

- Tensile Strength Test: The mortar prepared is placed in a mould of bricket which has central cross-sectional area as 38 mm × 38 mm. After curing the briquette [Fig. 3] is pulled under the grips of tensile testing machine. The ultimate load noted. Then the tensile strength of mortar is load divided by the central cross-sectional area.

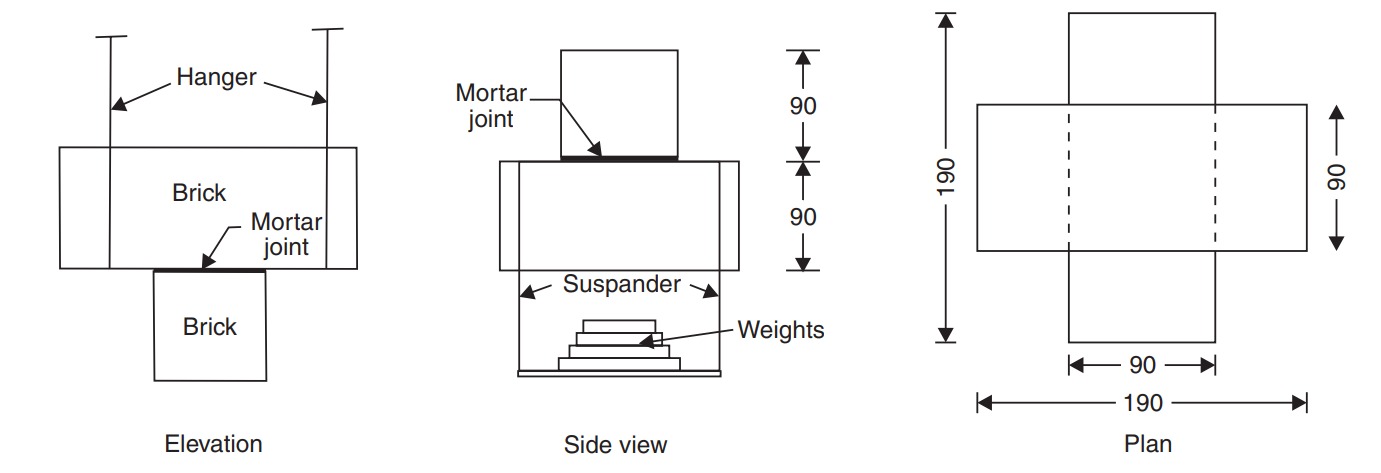

- Adhesive Test: Two bricks are joined together with mortar to be tested as shown in Fig. 2.4. The upper brick is suspended from an overhead support. A board is hung from the lower brick. Then weights are added to the board till the bricks separate. The adhesive strength is the load divided by area of contact.