Introduction

The Rankine cycle is a fundamental thermodynamic cycle that underpins the operation of steam power plants, a cornerstone of electricity generation worldwide. In this blog, we will delve into the intricacies of the Rankine cycle, exploring its principles, components, efficiency factors, and applications in power generation.

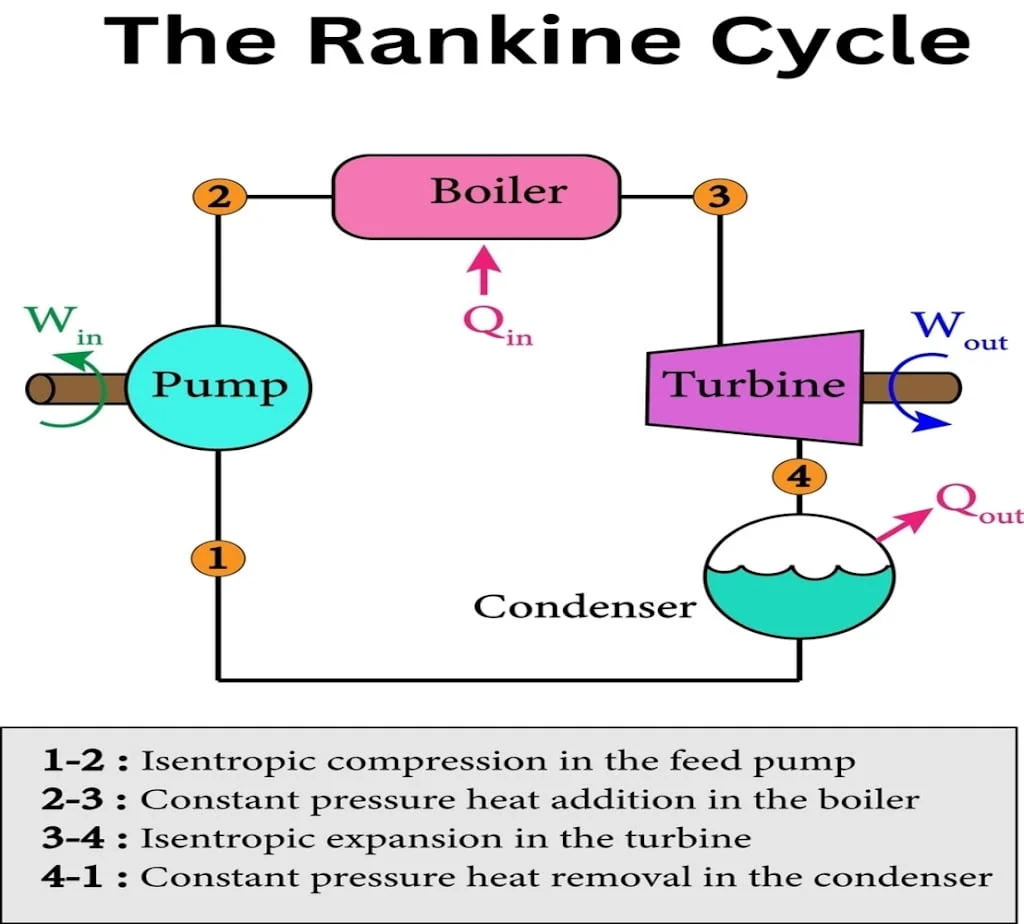

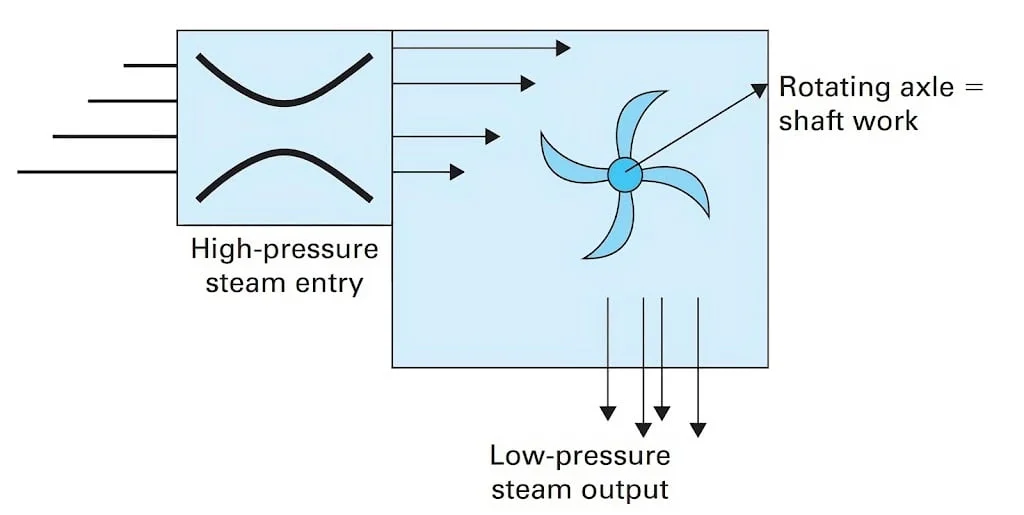

Figure 1

Understanding the Rankine Cycle

The Rankine cycle is thermodynamic cycle, which promotes the operation of steam plants and transforms heat energy into mechanical work and finally, electricity. It consists of four main processes:It consists of four main processes:

1.Heat Addition (Process 1-2)

The process starts with the production of heat in boiler at the constant pressure working fluid (typically water). This process we will be drawing line 1-2 on T-s diagram, where the cooling is taking place, resulting to saturated steam generation.

2.Expansion (Process 2-3)

Heat and pressure generated within a steam turbine execute work by expanding and converting some of its kinetic energy into mechanical work. This (1) expansion, which (2) graphically represented by the line 2-3 on the T-s diagram, shows how volume changes with temperature. The steam pressure and temperature decrease because the steam is expressing. The expanding steam is causing the spin of the blades, and as a result, rotational energy is generated.

3.Heat Rejection (Process 3-4)

Following passing the turbine, steam flows into an apparatus called a condenser, where it is cooled off and condensed back into liquid. It is the partial evaporation of water or the process of air conditioning that transmits heat to the medium (that is, the cooling fluid) at the same constant pressure represented by line 3-4 on the T-s diagram. During the process of the release of the heat energy in this latent form along with the transition from the steam to liquid state heat energy will be transferred to the cooling medium.

4.Compression (Process 4-1)

By this way every drop of the water is condensed and turned into a constant pressure water which is then fed back to the boiler. The phenomenon is termed as compression and represented on the T-s diagram by the line 4-1. The water is pressurized to boiler pressure, and it is ready to undergo both heat addition and circulation, resulting in a repetition of the cycle.

Working principle of Rankine cycle

The Rankine cycle converts heat into work. Figure 1 shows a schematic of the four steps of the Rankine cycle—boiler, turbine, condenser, and pump. This section explains the roles of each step.

- Burning fuel provides energy that must be converted into motion. Nozzles accelerate fluids, like in rockets where gases shoot downward fast, pushing the rocket upward by momentum conservation.

- Like garden hoses with nozzles (or using your thumb to speed up the water), the faster water flow gains kinetic energy, which comes from the fluid’s own energy.

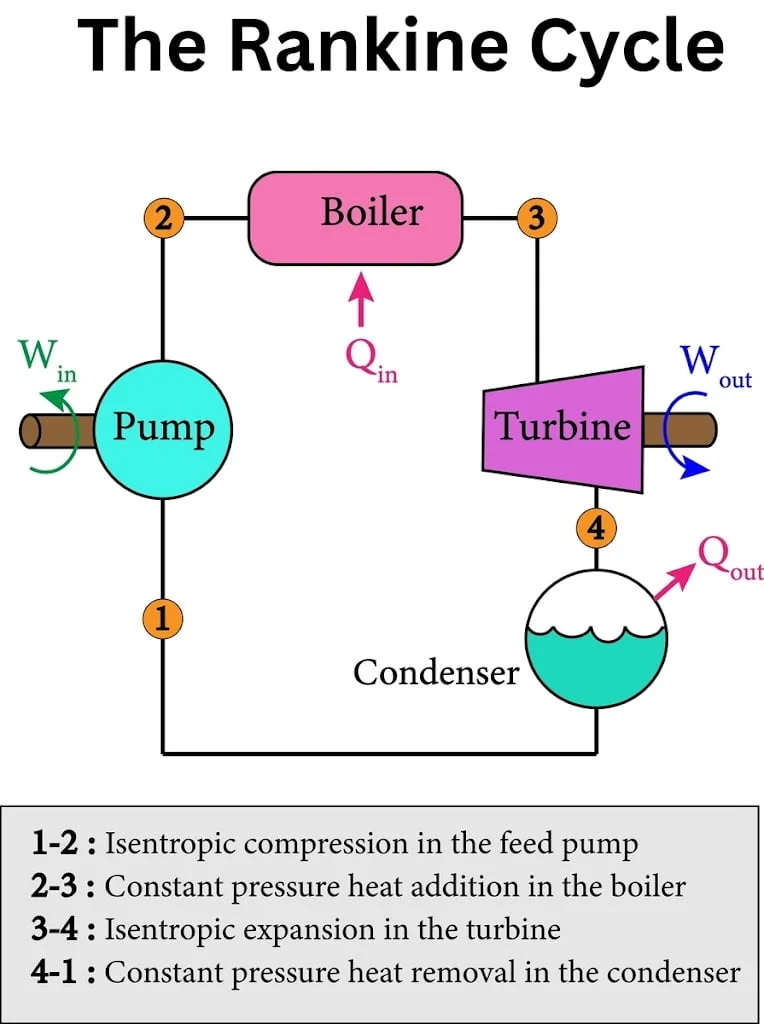

- Figure 2 shows a nozzle where steam enters at 5 bar and 450°C with negligible velocity, then exits at 1 bar and 228°C with a velocity of 669 m/s. The drop in temperature and rise in velocity show internal energy converting into kinetic energy.

Figure 2

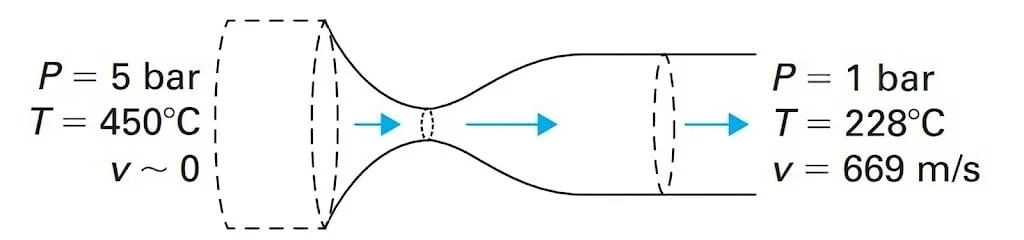

- A turbine (Figure 3) combines nozzles and windmills to convert internal energy into shaft work. It causes significant pressure drops, so high-pressure vapor—usually steam—is needed. Thus, in the Rankine cycle, the turbine receives high-temperature, high-pressure steam as the working fluid.

Figure 3

- Where does high-temperature, high-pressure steam come from? Compressing gases to high pressure requires much shaft work due to large volume changes. Using lots of work to compress steam before feeding it to a turbine would defeat the purpose.

- Since liquid volume is much smaller than vapor volume, compressing liquid requires far less work—often 100 to 1000 times less. In the Rankine cycle, the pump compresses liquid water to high pressure before it enters the boiler.

- Figure 4 depicts a boiler where fuel burns in the furnace; liquid water flows through coils inside and exits as steam.

In effect,

- The chemical reaction of combustion transforms the fuel's inherent energy into thermal energy.

- The influx of heat causes a rise in the water's temperature, which in turn elevates the water's inherent energy level.

- The rise in internal energy heats the water, causing it to boil into vapor and possibly warm further after vaporization.

- Low-pressure water cycles through a pump, boiler, and turbine to produce low-pressure steam. Continuously adding fresh water and releasing steam is impractical—for example, steam engines can't stop frequently to refill water. Instead, steam from the turbine cools and condenses back to liquid, which the pump returns to the cycle.

- Steady-state means process parameters remain constant over time (e.g., condenser output stays at 100°C).

- The Rankine cycle is a closed loop converting heat to work via a pump, boiler, turbine, and condenser.

- Energy fundamentally abides by a conservation principle: it's neither brought into existence nor does it disappear.

However, transformations between its various manifestations are possible. Engineers understand this core principle as the foundational law of thermodynamics. - An integral part of engineering practice is the design of processes that accomplish an objective. In the Rankine cycle, the objective is the conversion of heat into work.

- Burning fuels converts their internal energy into heat, which the Rankine cycle then transforms into work.

- A chemical process consists of unit operations, each with a specific function. The Rankine cycle involves four such units: a pump, a turbine, a boiler, and a condenser.

Chemical engineers use reactors, compressors, and separation units to process and separate materials.

- Many chemical processes operate continuously at a steady state. For example, electrical generation must run continuously to meet constant demand.

Efficiency Factors and Improvements

Several factors affect the efficiency of the Rankine cycle, including turbine design, boiler efficiency, condenser performance, and working fluid properties. Improving these areas can enhance the overall system efficiency and reduce environmental impact. Key advancements include:

- Superheating: Superheating increases the steam’s temperature beyond its saturation point, allowing the cycle to absorb additional heat energy and thereby improving turbine efficiency.

- Reheat Cycle: Reheat cycle involves steam extraction from the turbine partially expanded steam, re-heating in the boiler, and subsequently your steam expanded further in second stage of turbine. This minimizes moisture content and enhances turbine performance efficiency.

- Combined Cycle: Combined Cycle power plants increase efficiency by integrating a Rankine cycle with a conventional Brayton cycle (gas turbine cycle). The system transfers heat from the gas turbine to the Rankine cycle, producing additional steam and boosting overall power output.

Applications and Future Outlook

- The Rankine cycle powers coal, gas, and nuclear plants, efficiently converting heat into electricity.

- Over the past decade, engineers have enhanced Rankine cycle efficiency and sustainability by advancing turbine components and heat recovery methods. They also integrate renewables like solar and geothermal energy, promoting a cleaner, more sustainable energy future.

Conclusion

The Rankine cycle powers steam plants and is vital for global electricity generation. Its principles and efficiency are key to meeting energy needs sustainably. As technology evolves, engineers continue using it to develop efficient, reliable, and eco-friendly power solutions.