Introduction

The SCR plays a crucial role in power electronics because it accurately regulates electrical currents across a wide range of applications. In this comprehensive blog post, we will explore the complexities of SCR operation, highlight its key features, and examine the diverse ways engineers use it across different industries.

Understanding the Silicon Controlled Rectifier (SCR)

- The thyristor (SCR) refers to a family of power semiconductor switching devices known for their bistable switching action based on PNPN regenerative feedback. These devices contain four or more layers and at least three junctions. Among them, the SCR stands out as the most widely used and important member. It has revolutionized solid-state power control and, in most cases, people simply refer to the SCR as the thyristor.

- From a construction perspective, the thyristor (with a PNPN structure) essentially functions as a combination of two transistors—a PNP and an NPN—interconnected to form a regenerative feedback loop. The name “thyristor” comes from merging parts of the words thyratron and transistor. As a result, the thyristor operates as a solid-state device like a transistor but exhibits switching characteristics similar to a thyratron tube.

Working Principle of SCR

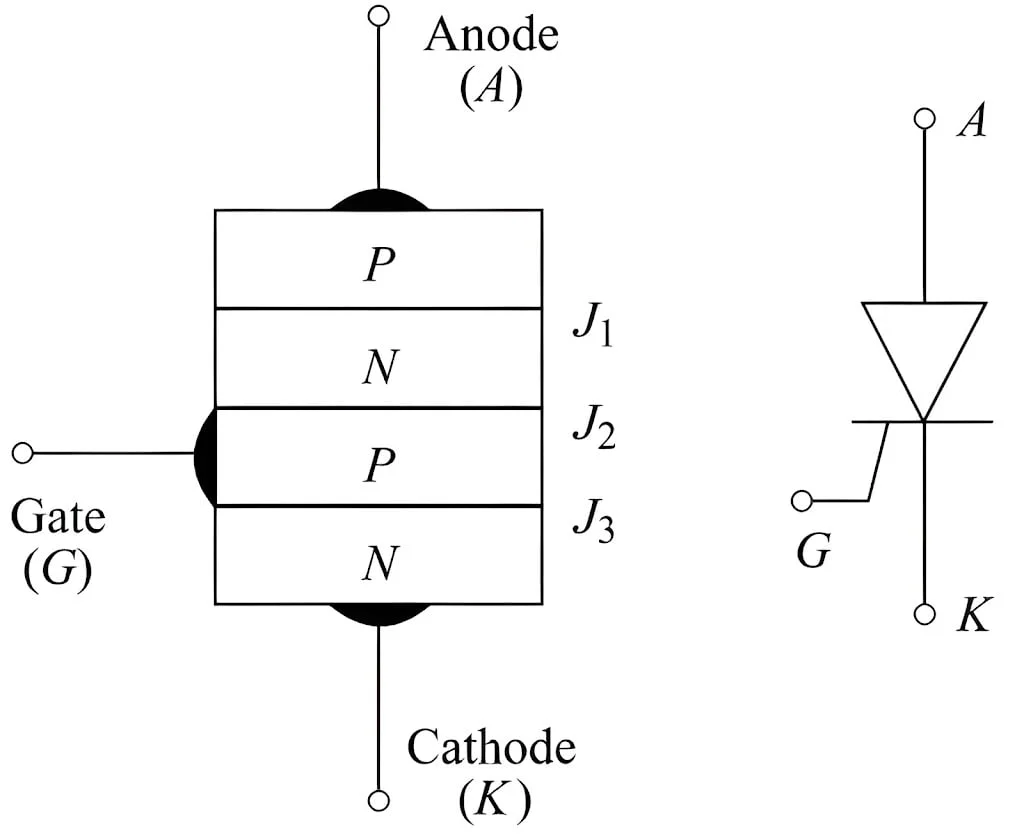

- Figure 1 shows the structure and symbol of a thyristor (SCR). This four-layer PNPN switching device contains three junctions: `J_1` ,`J_2` and `J_3`. It includes three external terminals—anode (A), cathode (K), and gate (G). The anode and cathode connect directly to the main power circuit. The gate terminal conducts a low-level current from gate to cathode. Designers typically place the gate terminal on the P-layer near the cathode, a configuration known as a cathode gate.

- With the outer P-region exhibiting a positive potential in comparison to the outer N-region, junctions designated `J_1` and `J_3` experience forward bias, facilitating current conduction. Nonetheless, the central junction, labeled `J_2`, stays reverse biased, consequently preventing a significant flow of current. Consequently, only a minor leakage current transits through the thyristor. This minute current arises due to the movement of charge carriers induced by drift.

- This current does not have enough magnitude to trigger conduction in the device. The depletion layer, made up mostly of immobile charges, prevents any significant current flow. In other words, the SCR remains non-conductive even under forward bias. Engineers refer to this condition as the forward blocking state or the OFF state of the device.

- When the end N-layer becomes positive with respect to the end P-layer, the middle junction `J_2` enters a forward-biased state, while the outer junctions `J_1` and `J_3` become reverse biased. These reverse-biased junctions block current flow, thereby preventing the device from conducting.

- A very small leakage current may flow due to the drift of charge carriers, but this current remains insufficient to trigger conduction. Engineers refer to this condition as the reverse blocking state or the off-state of the device.

- As the anode-to-cathode voltage increases, the width of the depletion layer at junction `J_2` decreases since this width is inversely proportional to the applied voltage. When the voltage continues to rise and reaches the forward breakover voltage, the depletion region at `J_2` collapses. At this point, the reverse-biased junction `J_2` undergoes avalanche breakdown due to the high voltage gradient across it.

This is called avalanche breakdown. With `J_1` and `J_3` already forward biased, the breakdown of the reverse-biased junction `J_2` enables free carrier flow across all three junctions. This causes a large current to flow from anode to cathode, switching the thyristor into its conducting or ON state.

Characteristics of SCR

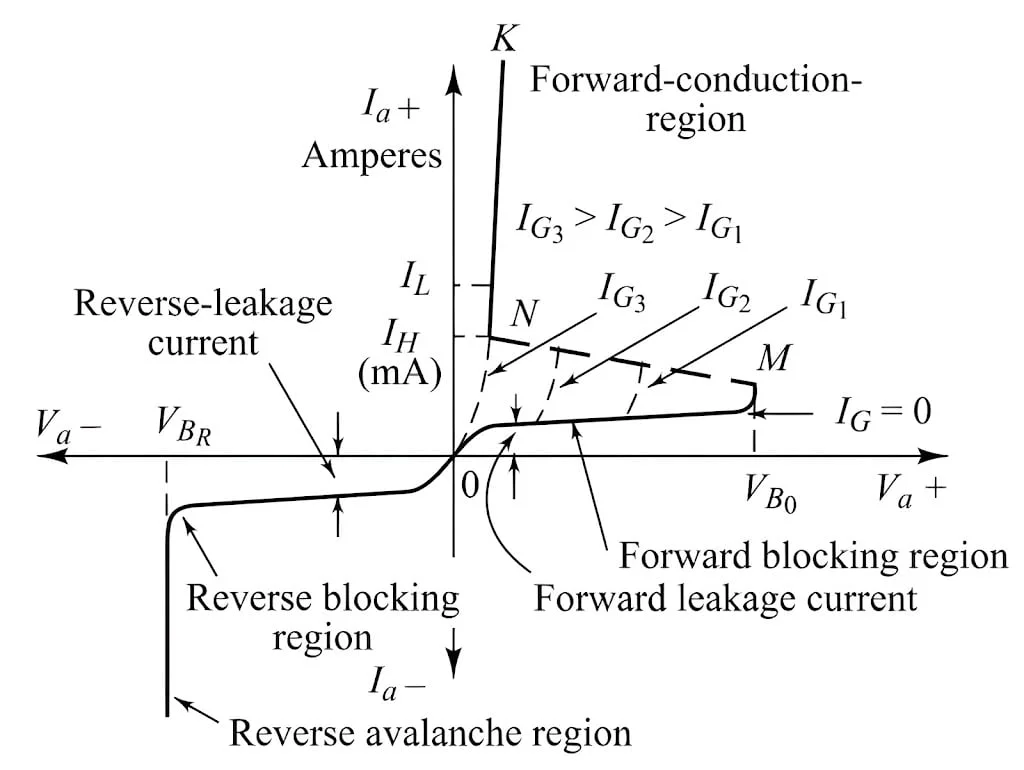

Figure 2 presents a basic circuit for obtaining the static V-I characteristics of a thyristor. The main power source connects the anode to the cathode through a load, while a separate source `E_g` powers the gate-cathode circuit. Figure 3 illustrates the V-I characteristics of an SCR, with `V_a` as the anode-cathode voltage and `I_a` as the anode current. The thyristor functions in three distinct regions, detailed in the following section.

1.Reverse Blocking Region

- With the cathode positively charged compared to the anode, and with switch S staying open (as illustrated in Fig. 2), the thyristor experiences reverse bias. Observing Fig. 3, we see in segment OP the reverse blocking zone; electrical current is inhibited, akin to how a diode functions. This is due to junctions `J_1` and `J_3` being reverse biased in this condition, while junction `J_2` is forward biased.

- Initially, the device allows only a small leakage current. As the reverse voltage reaches the reverse breakdown voltage `V_{BR}`, junctions `J_1` and `J_3` experience avalanche breakdown, sharply increasing current. Without limiting, this can damage the device due to excess power. Segment PQ of the V-I curve represents this reverse avalanche region. Below `V_{BR}`, the device behaves like a high-impedance open circuit in reverse.

- The inner two regions of the SCR are lightly doped compared to the outer ones. This causes the depletion layer at junction `J_2` (under forward bias) to be thicker than those at `J_1` and `J_3` (under reverse bias). As a result, the forward breakover voltage `V_{BO}` is typically higher than the reverse breakover voltage `V_{BR}`.

2.Forward Blocking Region

- In this region, a positive voltage is applied to the anode, forward-biasing junctions `J_1` and `J_3`, while `J_2` stays reverse-biased. This allows only a small forward leakage current to flow. Engineers label this part of the V-I curve as region OM—the forward blocking region—where the thyristor remains non-conductive.

3.Forward Conduction Region

- As forward voltage rises with an open gate, junction `J_2` experiences avalanche breakdown at the forward breakover voltage `V_{BO}`, switching the SCR into a low-impedance, high conduction state. In Fig. 3, point M indicates this ON-state transition.

- Region MN on the V-I characteristic shows that once the SCR switches ON, its voltage drops from hundreds of volts to around 1–2 volts, depending on its rating. A large current then flows through it. Region NK represents the forward conduction state, where the load impedance controls the anode current. In this mode, the SCR acts like a closed switch.

- When a gate-signal is applied, the thyristor turns-on before `V_{BO}` is reached.The forward voltage at which the device switches to ON state depends upon the magnitude of gate current; higher the gate current, lower is the forward breakover voltage. Figure 3 shows that for gate current `I_G` = 0, the forward breakover voltage is `V_{BO}`. For `I_{G1}`, the forward breakover voltage is less than `V_{BO}` and for `I_{G2}` > `I_{G1}`, it is still further reduced. In practice, the magnitude of gate-current is more than the minimum gate current required to turn-on the SCR. The typical gate current magnitudes are of the order of 20 to 200 mA.

- Once the SCR conducts a forward current above the latching current, the gate signal is no longer needed to keep it ON. Removing the gate current doesn't stop conduction. The SCR turns OFF and returns to its forward blocking state only when the anode current drops below the holding current (`I_h`).

Applications of Silicon Controlled Rectifiers

- Motor Speed Control: Engineers use Silicon-Controlled Rectifiers (SCRs) in motor drives and controllers to regulate electric motor speed and torque, ensuring precise control in industrial automation and automotive systems.

- Power Supplies: Engineers employ SCRs in Pulse Width Modulation (PWM) circuits to regulate rectifier-based DC power sources and voltage. This ensures stable DC output for electronics, consumer devices, and telecom equipment.

- Heating Systems: Engineers design electric heaters, furnaces, and heating elements using SCRs as temperature controllers. These devices commonly serve residential, commercial, and industrial heating applications.

- Light Dimmers: Designers often use SCRs in dimming circuits to control light intensity in homes, offices, theaters, and similar spaces. These circuits improve energy efficiency and allow precise brightness and ambiance control.

- Welding Equipment: Engineers use SCRs in welding devices to regulate the working current and voltage during welding, ensuring precise and consistent welding results.

- Power Factor Correction: Engineers employ SCRs in Power Factor Correction (PFC) circuits to improve system efficiency by adjusting the phase relationship between voltage and current, thereby reducing reactive power losses.

- High-Voltage Power Transmission: Engineers employ SCRs as core components in HVDC transmission systems to boost efficiency, enhance reliability, connect power grids, and facilitate the integration of renewable energy sources.