Introduction

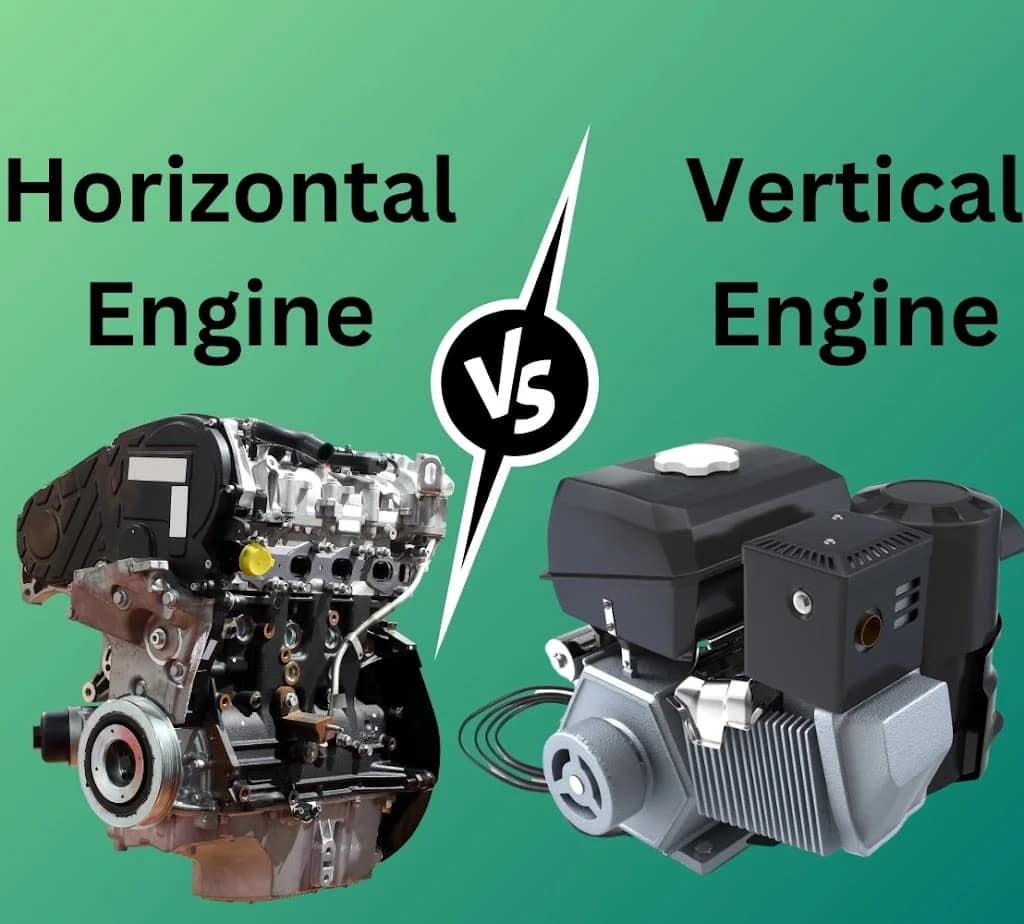

In engines used in vehicles, generators, and machinery, there are two popular configurations: horizontal and vertical. Every orientation comes with its own benefits and uses, which make them appropriate for various needs. In this blog post, we will explore horizontal engines and vertical engines in depth, examining their design, functionality, benefits, and uses.

What is horizontal engine and vertical engine?

The classification of engines hinges on the direction in which their pistons move. An engine falls under the "vertical" designation when its pistons execute an up-and-down motion.Conversely, the piston of a horizontal engine travels side to side.Reciprocating engines generate inertial forces stemming from the motion of their moving components. There are two main categories of forces at play, labeled primary and secondary. These forces directly correspond to the piston's movement and change depending on where the crankshaft is rotated. Ultimately, the overall action of these two types of forces results in the greatest force being transferred to the engine's crankshaft precisely when the crankshaft reaches Top Dead Center (TDC).It's important to note that the magnitude of both primary and secondary forces escalates proportionally to the square of the engine's rotational speed (RPM).

Horizontal Engine

Design and Functionality of horizontal engine

- In line with their name, the horizontals are crafter with cylinders that are in sequence with each other. This design allows having a lower center of gravity and hence making them well-suited for applications where the affecting factors of stability and space are important. As a rule, these engines are very broad and rather low they are in comparison to the vertical engines.

- The layout of a horizontal engine consists of crankshafts and camshafts aligned horizontally, which enables a wide ratio. This layout opens up not only repair services but also allows for the maintenance of parts that are readily accessible and placed at appropriate elevation.

Advantages of horizontal engine

- The placement of horizontal engines contributed to maintaining a low center of gravity. This design choice proves advantageous for machines where stability is paramount. Given their nature, such devices lend themselves to whimsical applications within equipment like lawnmowers, go-karts, and diverse industrial machinery.

- Although they are highly space-useful in terms of heights, getting engines are vertically applicable and well fit those programs where the vertical space is the limitation.

- Working with or over the horizontal type of engines is easier than with the vertical counterparts by replacing the crank and shaft and pistons.

- In a horizontally-oriented engine, the piston's motion occurs along a level line. The very nature of this engine's construction incorporates inertial effects.These arise from the engine's mobile elements. Therefore, both first-order and second-order forces play a role in its function.

- The composite force resulting from this integration imparts stress upon the vehicle's chassis.With the cylinder head positioned towards the front, the engine subsequently furnishes the impetus that drives the vehicle forward.

- It should be clear that when the piston is at BDC, then the impulsive force is the difference (not sum) between the primary and the secondary forces. When the piston is at TDC, both these forces combine together and increase the impulsive force.

- The engine's forceful, abrupt start amplifies a reaction: a forward shift. When set off, and uninhibited by friction, the engine will move. The forward motion results directly from the thrust created by an operating engine, especially when resting on a flat plane. Thus, a motor, employing a horizontally arranged piston stroke, naturally produces the forward motion of vehicles like scooters and mopeds, a consequence of the operational forces within.

Disadvantages of horizontal engine

- Due to its design, the crankcase is unsuitable for oil storage in a splash lubrication arrangement. Consequently, two-stroke cycle engines utilize a petrol lubrication system, while four-stroke cycle horizontal engines employ a pressure lubrication system.

- In the horizontal engine, weight of the piston is carried by the cylinder liner. This causes excessive wear at the lower side of the piston and cylinder liner where the cylinder liner gives support to the piston.

- The lubricating oil, which dribbles from the bearings does not return to the crank case but is thrown out by centrifugal forces. This cause more consumption of lubricating oil in a horizontal engine.

Applications of horizontal engine

- Lawnmowers and garden equipment

- Small generators and compressors

- Go-karts and recreational vehicles

- Industrial machinery and equipment

Vertical Engines

Design and Functionality vertical engine

- Vertically orientated engines run cylinders vertically as well as craft the crankshaft and camshaft directionally. The propeller shaft, along with the crankshaft, will often protrude from the bottom, which causes a narrower footprint of the vertical engine compared to horizontal engines. Apart from rocket engines, vertical engines can be successfully used under particular circumstances when the saving of area and easy installation are of utmost importance.

- The provision of a room for the vertical orientation of components in these engines can result in difficulties of accessibility for repairs and maintenance especially in tight spaces. Meanwhile, the design advancements have managed to mitigate various obstacles related to accessibility.

Advantages of vertical engine

- Horizontal engines have this particular advantage of saving space as they can simply be packed or mounted vertically. This makes them perfect for any small applications that operate from limited horizontal space like in lawnmowers, pumps or generators.

- Unlike traditional engines with their longer and wider configuration, vertical engines are typically much smaller and their vertical orientation makes the installation in different kinds of equipment and machinery much faster and easier.

- Furthermore, commonly the placement of engine vertically will ensure air circulation around it during operation, which in turn prevents overheating.

- The vertical engine has vertical stroke of the piston. The crankcase is at the bottom and stores lubricating oil for splash lubrication.

- The lubricating oil which dribbles from the bearings and other engine parts is collected in the crankcase and then reused after filtering.

- The weight of the piston is carried by the crank. Therefore, the weight of the piston does not wear the cylinder liner during motion.

Disadvantages of vertical engine

- In a vertical engine the primary and secondary forces caused due to inertia of the reciprocating parts combine together and produce tensile dynamic stresses on the foundation bolts.

- This gives vertical vibrations to the vehicle chassis frame,which can be felt by the passengers sitting in the vehicle.Also the foundation bolts may get fatigue failure.

Applications of vertical engine

- Lawnmowers and garden equipment

- Pumps for collecting and irrigation.

- Small generators and compressors

- These power machines are found on all type of vessels.